Plymouth, MN – ETP Shaft locking bushings from Zero-Max produce accurate and concentric mounting compared to mechanical shaft locking bushings.

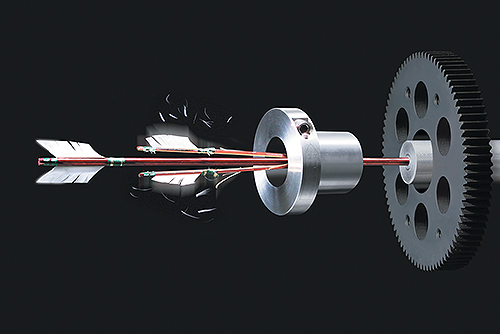

ETP bushings incorporate a double walled sleeve encapsulating a pressure medium. When the actuation screw is tightened it forces the inner and outer wall of the bushing to expand uniformly against the shaft and hub of the mounted component. The result is concentricity to .001” T.I.R. Mechanical devices, by comparison, rely on precise and accurate tightening of the actuation screws to avoid excessive T.I.R. Additionally, extremely high compressive forces are imparted on the shaft by mechanical bushings.

ETP bushings are ideal where repeated mounting and dismantling of components is required. ETP Bushings are consistently accurate and easy to use.

The ETP Classic has flange mounted actuation screws. The ETP Express has just one mounting screw positioned in a radial location. The single actuation screw of the ETP Express is the fastest and easiest way to mount components accurately. The single actuation screw saves space, time and is easy to access.

Both ETP Classic and ETP Express operate in temperature ranges from -22° to 180° F. The ETP Classic handles torque ranges from 40 to 11,413 ft lbs while the ETP Express handles torque ranges from 40 to 6,400 ft lbs. Both require no lubrication. They are available in a full range of inch and metric sizes in both standard steel and stainless steel.

Zero-Max

www.zero-max.com

::Design World::

Filed Under: Bushings • plain (sleeve) bearings, MECHANICAL POWER TRANSMISSION

Tell Us What You Think!