Since 1948, SPIROL has been helping companies lower their total assembled cost through innovative fastening and joining solutions. Over the years, SPIROL has grown to be a leading designer, manufacturer and supplier of engineered fasteners, shims, parts feeding technology and fastener installation equipment.

SPIROL has a diverse product offering including Coiled Spring Pins, Slotted Spring Pins, Solid Pins, Alignment Dowels & Bushings, Spacers, Compression Limiters, Inserts for Plastics, Disc Springs, Precision Shims, Fastener Installation Equipment, and High Performance Parts Feeding Technology. SPIROL has over 30,000 standard items, and is a distinguished supplier for leading manufacturers across a variety of industries including: Aerospace / Defense, Agriculture / Heavy Equipment, Alternative Energy / Green Technology, Automotive, Plastic Molding, Cosmetic, Durable Consumer Products, Industrial and Medical.

In addition to high quality products, SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and global stocking facilities to simplify the logistics of delivering your product.

Contact SPIROL today to partner on your next project!

Downloadable Resources:

- SPIROL Corporate Brochure

- Coiled Spring Pin Catalog

- Coiled Spring Pins for Cosmetic Cases Brochure

- Slotted Spring Pin Catalog

- Solid Pin Catalog

- Press-N-Lok Pins for Plastic Enclosures Brochure

- Latch Pins for Plastics Brochure

- Twist-Lok Pins for Plastics

- Alignment Dowels & Bushings Catalog

- Ground Hollow Dowels for Precision Alignment Brochure

- Spacers and Tubular Products Catalog

- Conveyor Spacers Brochure

- Garage Door Spacers Brochure

- Threaded Inserts for Plastics Catalog

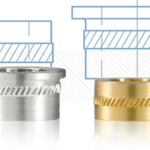

- Compression Limiters Catalog

- Disc Springs Catalog

- Precision Shims Catalog

- Fastener Installation Technology Brochure

- Series 2000 Vibratory Feed Technology Brochure

Featured Articles & Products Read More >

SPIROL’s new precision-machined compression limiters help protect plastic assemblies

February 9, 2024 2:00pmSPIROL introduces the new Series CL6000 lightweight, lead-free, Aluminum Precision Machined Compression Limiters. Compression Limiters are designed to reinforce high-stress joints in plastic assemblies where bolts are used to connect two components. They protect the plastic from excessive compression by absorbing the load when the bolt is tightened to the recommended tightening torque. This ensures the… [Read More]