(EAST PROVIDENCE, R.I.) — Igus® Inc. announced that Matrix Packaging Machinery has chosen it's DryLin® R linear bearings on its chief product line, the G Series packaging machines that includes the Matrix Proteus, Mercury and Ares.

Matrix manufacturers vertical, form, fill and seal (v/f/f/s) packaging equipment, which handles a wide range of products from green beans to candy to detergent.

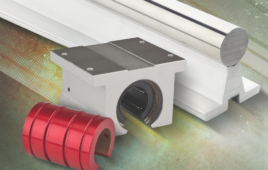

Matrix’s G Series machines operate in many diverse environments, which compelled Matrix to find a bearing that would operate seamlessly while in continuous contact with environmental elements such as dust, dirt and water. Matrix chose DryLin® R linear bearings made of highly engineered plastic so they need no lubrication or maintenance. DryLin R bearings are formulated for long-life and consistently low friction.

Matrix uses DryLin R sleeve bearings designed for easy installation and removal in the most extreme applications, such as those seen by Matrix packaging machines. The bearing is comprised of two parts: a plastic liner made from igus’ iglide J200 material that can be pushed easily onto the shaft and a split aluminum adapter that fits over the liner.

This particular bearing delivers many advantages for both Matrix and its customers. Installation time is greatly reduced because Drylin R eliminates the need to remove the shaft from its housing. If replacement is necessary, the adapter shell opens effortlessly and only the plastic liner needs to be replaced. This feature saves the customer time, and in some cases, can reduce replacement part costs by 90 percent.

With DryLin R, Matrix customers rarely experience bearing failure on their machines. The company’s expectations were exceeded when DryLin R endured seven million cycles on its G Series with little to no noticeable wear, and to date, some of the machines have surpassed the 10-million cycle mark with DryLin R still in operation.

In the past, Matrix employed metal ball bearings in its packaging machines. After encountering scored shafting and grease leaks on some machines, Matrix made the switch to DryLin R. After doing so, the company has noticed little to no shaft wear and a slight increase in production due to the lighter weight of DryLin.

Matrix uses DryLin R linear bearings on its G Series machines, which are capable of reaching up to 160 cycles per minute. DryLin R manages loads up to 15 pounds on each machine, while operating at a speed of 750 feet per minute. Matrix machines also use iglide Z from igus, a line of plastic bearings suited for applications with high temperatures, extreme loads and high surface speeds.

:: Design World ::

Filed Under: Bearings, Packaging

Tell Us What You Think!