A large ring gear with supporting cam followers mounted internally. Two of the cam followers have eccentric shafts.

This novel gear-bearing, which uses motion components made from advanced polymers, is an alternative to large outer diameter bearings to support large ring gears or other large rotating components.

When a design calls for a large bearing — for example, to support a large outer diameter (OD) ring gear — choosing a sturdy yet lightweight mechanism with the properties and stability for reliable performance can be challenging. Finding an appropriate bearing that can operate in a hygienic clean room, food processing, or vacuum environments can be an even greater challenge.

The list of bearing considerations is lengthy, and it includes accuracy and rotational tolerances, load handling capabilities, maintenance, and cost. One factor that’s central to these considerations is the construction of the bearing and its constituent components. Not only must the bearing support accurate, efficient motion, but it must satisfy the need for lighter designs, which has been a constant trend across many industries and applications. And if the bearing’s intended environment is a vacuum, it can’t disperse any contaminants. At the same time, lubrication is not an option, making your material selection critical.

An example of an iCam cam follower support arrangement on the outside of a ring.

Unique design and materials excel in heavy-duty applications and difficult environments

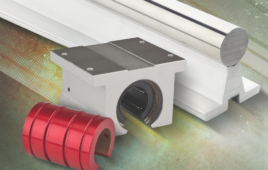

An example of a component that overcomes these issues is a versatile, large gear-bearing that is well-suited for hygienic or demanding environments and for other applications that demand precise rotary motion and lightweight designs. This unit has a novel design that combines several motion components into one: a large ring gear supported by several individually mounted guide rollers or cam followers driven by a pinion. The large ring gear is typically made from aluminum, and the pinion and supporting guide rollers are made from an engineered polyamide-based thermoplastic material. When the unit must operate in a vacuum, the gear is constructed from stainless steel.

The large ring may have an internal gear, or the teeth can be machined outside the ring. Spaced around the perimeter, mounted inside or outside the ring gear, are the supporting cam followers that locate the gear in place, axially and radially, and enable the rotating motion. By using engineered polymers as the bearing surface, these cam followers can withstand large forces, have a long wear-life, and offer many additional advantages.

To accommodate the application’s space restrictions, the PowerCore pinion, and the guide roller was designed as one unit. The guide roller’s OD prevents the gear teeth from bottoming out.

Advantages of hybrid construction

Engineered polymers offer several advantages over other materials. Due to its high crystallinity, the material can handle high mechanical loads that are prohibitive to plastics, and it even exhibits higher strength than similar injection-molded polymers. In fact, some larger structural parts made from this material can withstand continuous forces of several metric tons. Despite the advanced polymer’s high strength, it’s also very lightweight and is seven times lighter than metal, which can benefit high-speed applications where inertia mismatches can affect machine performance.

Together in this unique design, the aluminum and polymer materials create a lighter gear-bearing unit and deliver a host of benefits for a wide range of applications:

● Lighter weight. Combining the large gear’s aluminum, the drive gear’s engineered polymer, and the rotational support by individual cam followers results in a lightweight, simpler design that reduces inertia.

● Precision rotation. The precision-machined outer guide rollers have a maximum OD tolerance of 0.004-in. and closely match the pitch diameter tolerances on the large ring gear. Additionally, selectively placed eccentric guide rollers can tighten up any slag.

● No backlash. Besides the traditional methods to reduce or eliminate backlash in gears, engineers have developed several tooth mesh modifications for reducing or eliminating backlash. These modifications take advantage of the engineered polymer’s elastic properties. In addition, the pinion has a cast-in metal core for secure attachment to a shaft and reduces up to 50% of the thermal expansion of the plastic portion of the gears. The polymer remains dimensionally stable under varying process conditions and in moisture, contributing to backlash-free rotation.

● No need for lubrication. The polymer material used for the gears and cam followers is maintenance-free, eliminating the need for lubrication — even when running on aluminum, carbon, or stainless steel.

● No metal particulate contamination. The polymer gears, cam followers, or guide rollers don’t wear out metal. As a result, they don’t generate metal particles, which is an important feature in many industries and processes.

● Reduced noise. Because of its shock-absorbing properties and precision machined surfaces, the polymer reduces noise in gears by up to 6 decibels — and up to 10 decibels compared to metal cam followers.

In addition, the large-diameter integrated gear-bearing design is especially suited for harsh environments. The bearing is suitable to work in a vacuum. The large gear is available in a stainless-steel version; together with lubrication-free polymer and guide rollers with ceramic bearings, this construction makes the large gear-bearing desirable for vacuum environments where metal particulates, outgassing, and other contaminants released by greases are major concerns.

The type of bearing also provides chemical and corrosion resistance. A 316 stainless steel metal core for the drive pinion can be specified. Additionally, highly crystalline polymer withstands continuous exposure to many chemicals, including silicon vapors. The polymer does not absorb moisture, and the integrated gear-bearing is suitable for equipment subject to washdown.

The supporting cam followers, spaced around the perimeter of the ring gear, locate the gear in place both axially and radially. The bearing surface profile can be designed to suit the application. For higher loads, additional cam followers can be used.

When a large bearing must meet strict requirements, achieve a long operating life, or run without lubrication, chances are a standard bearing might not be an option. To achieve optimal accuracy, performance, and service life, this large-diameter gear-bearing can be modified to meet unique requirements. For example, gear train modifications can reduce friction and backlash, dissipate heat, increase load capacity, raise transmission efficiency, and lower power drive requirements to ensure the components perform optimally. The design of the guide rollers and cam followers is often also customized — from the shape of the bearing surface to customized shafts, to bearing selection.

Leveraging the benefits of high-performance polymers

Designing large bearings for demanding vacuum environments comes with much uncertainty. Not only must a bearing provide highly accurate motion, but it must operate reliably without lubrication. And as more industries emphasize lighter components, engineers and installers should take a closer look at the materials that comprise their bearing.

This unique and versatile large gear-bearing design leverages the mechanical strength and stability of a crystalline polymer to deliver high performance with minimal backlash and noise, all while satisfying the demands for lightweight, zero maintenance, and cost savings.

InTech

www.intechpower.com

Filed Under: Bearings