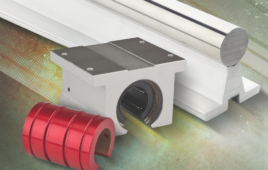

Parker’s (www.parker.com) OSPP-BG Pneumatic Linear Drives feature a plain bearing guide that is directly integrated into the cylinder barrel. Eliminating the need for piston rod, the pneumatic linear drives offer long service life, smooth operation and high service intervals.

Longitudinal slot within the cylinder is protected and sealed by stainless steel bands while the piston features support rings, piston yoke, cushion seals, piston seals, magnets and bearing strips.

With the load mounted on the carrier, the guide can be easily re-adjusted with screws. From the air connection, the air supply passes via the cushion spigot going to the cylinder barrel.

End cushioning is produced by compressing the space around the cushion spigot in between the cover and the cushion seal, at the end of the cylinder barrel. It can also be adjusted at each end of the cylinder using a needle valve.

The OSPP-BG Pneumatic Linear Drive is designed with a cylinder that has permanent grease lubrication. Its plain bearing guide, on the other hand, can be re-lubricated using the integrated grease nipples.

Compressed air moves the piston within the linear drive. Initially, both sides of the cylinder are charged with compressed air while the side where the user prefers the piston to move is vented. Users can also use various types of control for special applications provided that other parameters are also considered.

Offering a stroke length of up to 6,000 mm, the OSPP-BG Rodless Pneumatic Linear Drives are also available in stainless steel version. For stick-slip free operation, Parker also offers a slow running version.

Filed Under: Actuators, Bearings, Pneumatic equipment + components, Pneumatic Tips