The Brightware Insights software application focuses on delivering manufacturing process improvements through data analytics and easy to interpret visualizations, available on the edge and in the cloud.

Brightware Insights is the second offering in Bright Machines’ growing product portfolio. It complements the existing Brightware Studio offering (launched in  September 2021) by driving actionable insights that can help optimize production efficiency, improve quality, and increase equipment uptime. Each Brightware application also offers additional functionality on top of the Bright Machines Microfactory – the Company’s flagship solution for flexible assembly automation.

September 2021) by driving actionable insights that can help optimize production efficiency, improve quality, and increase equipment uptime. Each Brightware application also offers additional functionality on top of the Bright Machines Microfactory – the Company’s flagship solution for flexible assembly automation.

This new application will enable global manufacturers to improve their factory operations by analyzing key performance indicators using data aggregated across microfactories. Using a cloud-based application architecture, Brightware Insights provides standardized data modeling and visualization templates tailored to a range of users, from quality and process engineers on the factory floor to manufacturing leaders at the plant and corporate level.

“Our customers understand that intelligent automation reduces much of the complexity in manufacturing, helping them to be more responsive and flexible in a dynamic market environment,” said Lior Susan, interim CEO & Co-Founder, Bright Machines. “Brightware Insights extends our current full-stack offering with enhanced functionality that equips manufacturers with software to better understand their operations and drive process improvements with meaningful business impact.”

Brightware Insights Enhances Factory Operations:

Works out of the box: Pre-integrated with Bright Machines Microfactories and Brightware Studio, Brightware Insights works from the first day of deployment. Data is collected and visualized through customized dashboards tailored to different user types. Because the software integration work is done upfront, the time to value is accelerated.

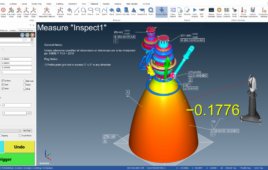

Enables data-based decision-making: Brightware Insights makes it possible to leverage operational and product traceability data to drive process improvement decisions on the production line. Data visualizations are easy to review and interpret by manufacturing employees at any level.

Gives users access from anywhere: Customers can access and view process data from anywhere via cloud dashboards.

Advanced Analytics Starting at Deployment:

Performance benchmarking: Brightware Insights standardizes data that is captured, so comparing performance across multiple microfactory lines is possible. This further allows for greater process standardization across a company’s manufacturing facilities.

Trend analysis: Brightware Insights has the capability to ingest all the data coming from a customer’s microfactory lines and store it in the cloud. Correlations and trends can be spotted in the historical data, providing a deeper understanding of what is happening on the microfactory lines.

Traceability: The ability of Brightware Insights to leverage product-level data is also intended to enable product traceability and diagnosis of production issues, especially when unexpected anomalies occur. This can help increase supply chain visibility, improve quality control, and reduce risk.

“Traditional factory automation often lacks the seamless data integration that manufacturers need for multi-line optimizations, making large-scale production upgrades challenging and limiting business value,” said Abhishek Pani, CPO, Bright Machines. “Brightware Insights makes it possible to directly access meaningful decision-making data, not only for engineers on the factory floor but also for the managers responsible for automation projects across locations.”

Bright Machines, 585 Howard Street, San Francisco, CA 94105, (415) 820-5000, www.brightmachines.com/

You may also like:

Filed Under: Factory automation, Software • CAM, MOTION CONTROL