Some people have a project car. Weekends and evenings are spent tuning, working Bondo and fiberglass to patch holes, cursing the frustrations of electrical work, and relishing the feeling when the engine roars to life for the first time. My ‘project car’ is actually a Rotorway JetExec helicopter. Same journey, same payoff, slightly different license required to operate. So in honor of National Aviation Day, I am going to share the story about how a month ago, I found myself getting my airworthiness certificate for my own experimental home-built helicopter. This blog post dives more into the “build and test” aspect of helicopter design, but I’ll be sure to offer some simulation eye candy at the end!

Unlike a project car, I didn’t find her on the side of the road rusty and ready to be trailered home. I would consider it a little bit of “right place at the right time” except I suppose I wouldn’t have been at that place had I not been researching gas turbine engines at Purdue. It came to me at the Irish pub I was working at through Grad School. My friend who worked at the pub with me happened to be chatting with one of our regulars about this helicopter project and so he had to bring me into the conversation. Though the patron had worked out the plans and purchased all the parts to assemble the craft, he was in need of assistance for the construction of it and asked us if we knew anybody at Purdue. Of course, we knew people, we knew it had to be us!

Figure 1: The beginning of the journey

And so we spent the next year working with him on the build. Long story short, after he passed away that year, we purchased the parts and continued the work in Indiana. Eventually, I became the sole owner, moved across the country to New Hampshire, and have been working on her ever since. I am now in year eight of the build.

Believe it or not, we originally had thought it was only going to take one year to complete the build. Since then, my motto has become “I have to set a target date so I can get started on missing it.” Without fail, every task takes longer than you think after you factor in all the studying, trial, and error required. That, and juggling a hobby with a full-time job.

Every project has elements to it that you know that you don’t know, but there are so many things you don’t know that you don’t know when building a helicopter. That is one of the biggest time sinks. And when it’s a helicopter with your own life involved, you need to do something enough times until you trust your own work. That trust only comes by doing, undoing, and doing again until eventually you’re undoing less than you’re doing. The electrical was a prime example of this; I believe I have laid every wire in that helicopter at least three to four times before I found it acceptable.

Figure 2: One of the first times the engine and drivetrain were installed.

But the biggest hurdle has to be that virtually nothing can be googled. I have to completely get my head around a problem to come up with a solution rather than look up that solution online. You have to understand all the disciplines a master mechanic would know. Trying to work out where to mount the antenna? Better study antenna theory. Setting up avionics? Become a master of professional wire looms. Making changes, adjustments, or fixes to the body panels? Become a master autobody mechanic.

The other element to successfully overcoming challenges is getting comfortable with the fact that nothing is ever fully finished. Each time I have thought I had completed a section, ready to check the box and move on, something else would come up that necessitated tearing it all back apart again. Just last winter after she had already hovered successfully, I had to tear apart the entire drivetrain for one minor fix. Perhaps with my next helicopter I’ll know all the tricks to apply the first time, but this one required many iterations before I got it right.

Luckily, there is a small community of a couple of dozen people who have done this. I’m certainly not the first. Some of the issues I’ve encountered have been seen before and it’s a matter of making phone calls to get to the right person or finding someone with experience that can help brainstorm. For the most part, we all aim to help each other. When I heard someone else in the community suffered a fracture on their tail rotor, I designed an assembly and brought in another engineer friend who fabricated it. Since it is a component critical for safety we provided it to others in the community to install on their crafts. There have been multiple owners who have implemented this fix.

The engine that powers mine is a Solar gas turbine, which is an old military surplus engine that was primarily used in APUs (Auxiliary Power Unit) to provide power to mobile military bases. Mine was used in the ’70s. Once these engines were decommissioned and refurbished, the experimental aircraft community picked them up. Since a helicopter requires constant RPM throughout the entire flight, a gas turbine engine is an ideal power plant.

Having the hobby follow so closely to my professional background has certainly been helpful. Having worked primarily in turbomachinery gives me a leg up on the fundamental physics inside the engine. When something isn’t operating correctly, I can generally rely on my coursework to diagnose the problem. Understanding the fundamental operation of a turbine engine and how to prevent compressor surge during acceleration, for instance. Or referring to my controls engineering courses when tuning the electronic governor system to regulate the fuel control. Or designing the circuitry for the engine and gearbox instrumentation.

But theory and brute force alone weren’t enough to make her airworthy. I needed wisdom and experience, so in 2019 I brought the craft to Missouri to work with one of the foremost experts in the field. The very first day working with him I was scared to open the door to the trailer and show him my work, since I‘m a newbie and he is one of the experts in his craft. How would he consider what I had spent the last 6 years building? Would he think it was terrible and make me tear it all back apart again? If so, could it be fixed? How much time would that take? I was fully expecting him to find many things I had done wrong. But instead of all that, he shared many of his tips and tricks he had learned over his career and we went through everything with a fine-tooth comb. I learned more about aircraft building from working with him for a few days than I had in the previous 2 years.

After he had gone through everything in the engine bay, cockpit and tail, it was time to mount the blades for the first time and do the precision work of static and dynamic balancing. Here again is an example of how my degree helps me make sense of the complex physics involved with balancing an articulating rotor system.

And then…despite playing it over and over in my head for several years I can’t fully describe the feeling of what it was like when she lifted off the ground for the very first time. Several times over the course of two days we ran the engine up to full RPM, and he tested whether it felt ready to take off yet before he shook his head and said he needed to make an adjustment and then shut it back down. But one of those times, he instead said “yeah, feels good, here we go.” and off we went. It lifted off gently, like a magic carpet and we moved out into the field to begin testing some gentle maneuvers.

A year later, I was able to meet up with him again in New Hampshire. I had completed a few homework assignments over the winter, and so we went over the craft again, and then we began my part of the flight training. We start with hovering, which I had been warned was “hilariously hard”. But it’s also just as important for the craft as it is for the pilot in training. During near-ground hover, the engine is working the hardest of any time during a flight, and so it provides a stress test for the engine while also remaining a safe few feet off the ground. While you’re learning it’s an intense brain exercise. Every action you make requires three inputs in unison between your feet and both hands, and you never feel like you’re stable or like it’s coasting. By the end of a day of training, you’re mentally exhausted. The training period on hover alone is somewhere around 20 hours, and I’m certain to need all of it before I transition to the next part of training – bringing it up to altitude.

Figure 4: The completed project

And rather fittingly, this National Aviation Day finds me continuing the official test flight plan, the final step before the official endorsement of the helicopter and the completion of my training and the freedom to fly.

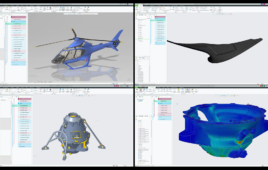

But of course, this wouldn’t be a Rand SIM blog post if I didn’t at least show some simulation I made of it in CFX. The below animation shows how easily CFX can incorporate multiple rotating bodies simultaneously and provide realistic pressure contours on the surface of the craft. Such information could be used for macro-level tracking of lift and drag, or to identify the magnitude of aero-induced oscillations.

Figure 5: Unsteady pressure contours on the surface of the craft during level flight, as simulated by ANSYS CFX.

Filed Under: Aerospace + defense, Software • 3D CAD