Edited by Mike Santora

For employees packaging cheese on a tray line at Alpine Slicing & Cheese Conversion, the repetitive motion of reaching out and grabbing packaged cheese trays has a tremendous impact on their bodies. As for how to fix that, it’s a matter of inches. When it came time to expand its contract packaging services by adding a second tray line, Alpine was looking for new ideas to improve upon this process…and they found the solution through an adjustable sanitary conveyor system from Dorner Mfg.

Not measuring up

The original tray line is functional as it moves packaged cheese trays to the pack out station for shipping, but it could have been designed better.

After cheese trays are packaged from the sealer machine and pass through a metal detector, they transfer onto the first AquaPruf conveyor that’s positioned at 25° incline angle. This four-foot long conveyor brings packaged cheese up to proper height for handling, and also uses a higher friction belt to prevent the trays from slipping.

“The height on the tray line isn’t exactly where we want it to be,” said Jim Natzke, manager, Alpine Slicing & Cheese Conversion. “For some of our employees they were hunched over a bit. Just that little bit of extra reaching adds up, and people can get sore backs. Our goal with the new line was to eliminate that condition and make things more ergonomically correct for our employees.”

As the need for a second tray line became clear to leadership, the task of heading up that project fell to Natzke.

“Knowing the limitations of our original tray line, we thought for this new one let’s just approach it differently and see if we can do it better,” he said.

On the original tray line, cheese is sliced, packaged and placed onto a conveyor, which passes product through a metal detection unit. Then, the conveyor deposits the cheese onto a large rotating lazy Susan-type round table, which is used to accumulate cheese as two employees grab the packages and load them into packing boxes in preparation for shipment.

The main issue with this line is the height of the conveyor and position of the rotating table, both of which are a few inches lower than Natzke would like. This leads the employees packing cheese from the line to constantly be bending over to grab the cheese from either the conveyor, or reaching out to get cheese trays from the rotating table. The process was causing the employees to perform a lot of extra motion to package cheese, and that was one thing Natzke wanted eliminated with the new line.

Collaborating on a new idea

This new design, which was installed in fall 2015, offers several advantages over the original tray line. First, the conveyor system, along with that attached packout table, can be raised or lowered to best compliment different employees for better ergonomics.

Natzke contacted Dorner and posed the application challenge to Marie Wiese. “The packaging of cheese once it comes out of the sealer is a manual process at Alpine Slicing, and it wasn’t very ergonomically sound,” said Wiese, sales manager for Dorner’s Engineered Solutions Group. “We recently had a similar challenge with another cheese manufacturer, and I thought a comparable solution might work.”

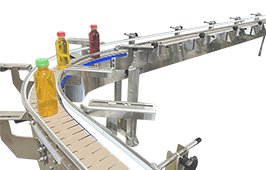

That solution involved two Dorner AquaPruf conveyors, along with a packaging table – all of which are adjustable in height to accommodate Alpine Slice’s employees. After cheese trays are packaged from the sealer machine and pass through a metal detector, they transfer onto the first AquaPruf conveyor that’s positioned at 25° incline angle. This four-foot long conveyor brings packaged cheese up to proper height for handling, and also uses a higher friction belt to prevent the trays from slipping. Then, the trays are transferred to the final seven-foot long AquaPruf conveyor. A stop at the end of the conveyor, fitted with a low-friction belt, allows trays to slide in place if the line begins to back up.

With the new design the conveyor system can be raised or lowered for different employees. Trays also arrive to the pack station properly oriented, making it easier for employees to handle. The whole process can now be handled with one less person as opposed to two employees typically staffed on the original tray line. Adjustable conveyor guiding means the line can be adjusted to accommodate different size trays. Finally, the conveyor system has a reversing center drive, enabling it to be repurposed to a different area and fed from the opposite direction if needed.

Dorner Mfg.

www.dornerconveyors.com

Filed Under: Conveyors

Tell Us What You Think!