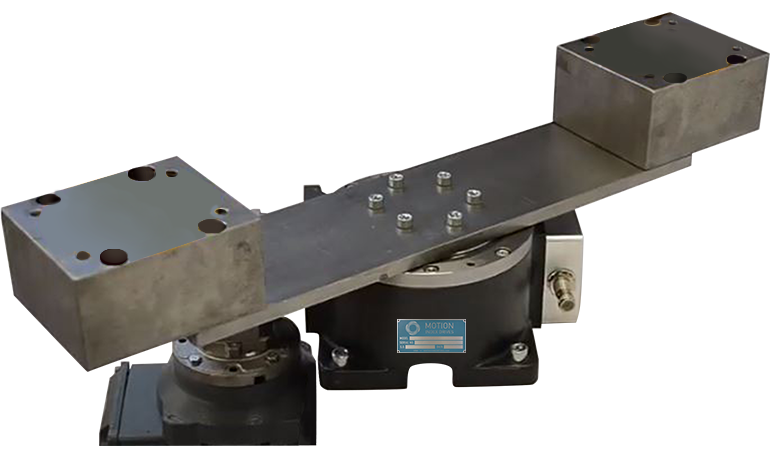

RTX350/10 used in a battery manufacturing facility

Motion Index Drives is here to help manufacturers adapt in this progressive shift into Electric Vehicle Production with a variety of precise and flexible solutions to improve the efficiency of EV battery manufacturing.

The new RTX350 high speed cam indexing rotary table is our newest and smallest indexer of our extensive line of cam indexers. Several hundred of these new RTX350/10 ten station and six station rotary indexers will be utilized in a battery manufacturing facility in Germany.

The index time for these units is 0.25 seconds for 36 degrees. The video is simulating the inertia load of the actually application that will be used for production of batteries.

The indexing rotary table RTX is often used in the assembly technology, the testing technology, the welding technology, the printing, the pressing, the automotive industry, the microelectronics, the food industry, the medical and the cosmetic industry.

Features

- Reliable, robust drum cam roundtable for all applications

- Construction diameter 100mm – 500mm

- Fixed divisions 2 – 96 or flexible through NC technology

- Switching times of 0.16s – 5s

- Gentle starting and stopping across the switching cam

- Large, vertically hollow shaft

Benefits

- Ideal for high loads

- Standard accuracy 15″ – 35″

- Four-point mounting at the outer diameter output flange

- Maintenance free through oil bath lubrication

- Stop operation, continuous operation or reversing design possible

- All installation positions possible

LFA HSP is the answer to today‘s questions in modern manufacturing. Our new linear transfer system keeps up with the ever increasing demands for shorter indexing times and higher precision.

Its geometry is designed for high speed, energy efficiency and higher loads. It applies to continuous and intermittent processes.

Motion Index Drives LFA HSP allows to ramp up production and lift the output to the next level. Typical feed times with a total load of 200kg are as follows: With torque motor, even shorter times are possible.

Advantages

- Short indexing times: the geometry of the U-turn is designed to compensate radial forces.

- Precision of +/- 0.05 mm: the system inherits position accuracy two servo motors.

- Energy efficient: custom acceleration ramps reduce the power consumption of the system.

- Constant velocity: new possibilities for operations in motion.

- Quick setup: no programming of individual carriers.

- Low-maintenance and robust: no fine tuning in operation necessary.

Applications

- Cell assembly

- Cell Cleaning

- Protective Painting

- Cell Taping

- Cell stacking

- Modul pack assembly

- Visual testing (optical, x-ray)

Sponsored content by Motion Index Drives

Filed Under: Motion Index Drives Sponsored Content