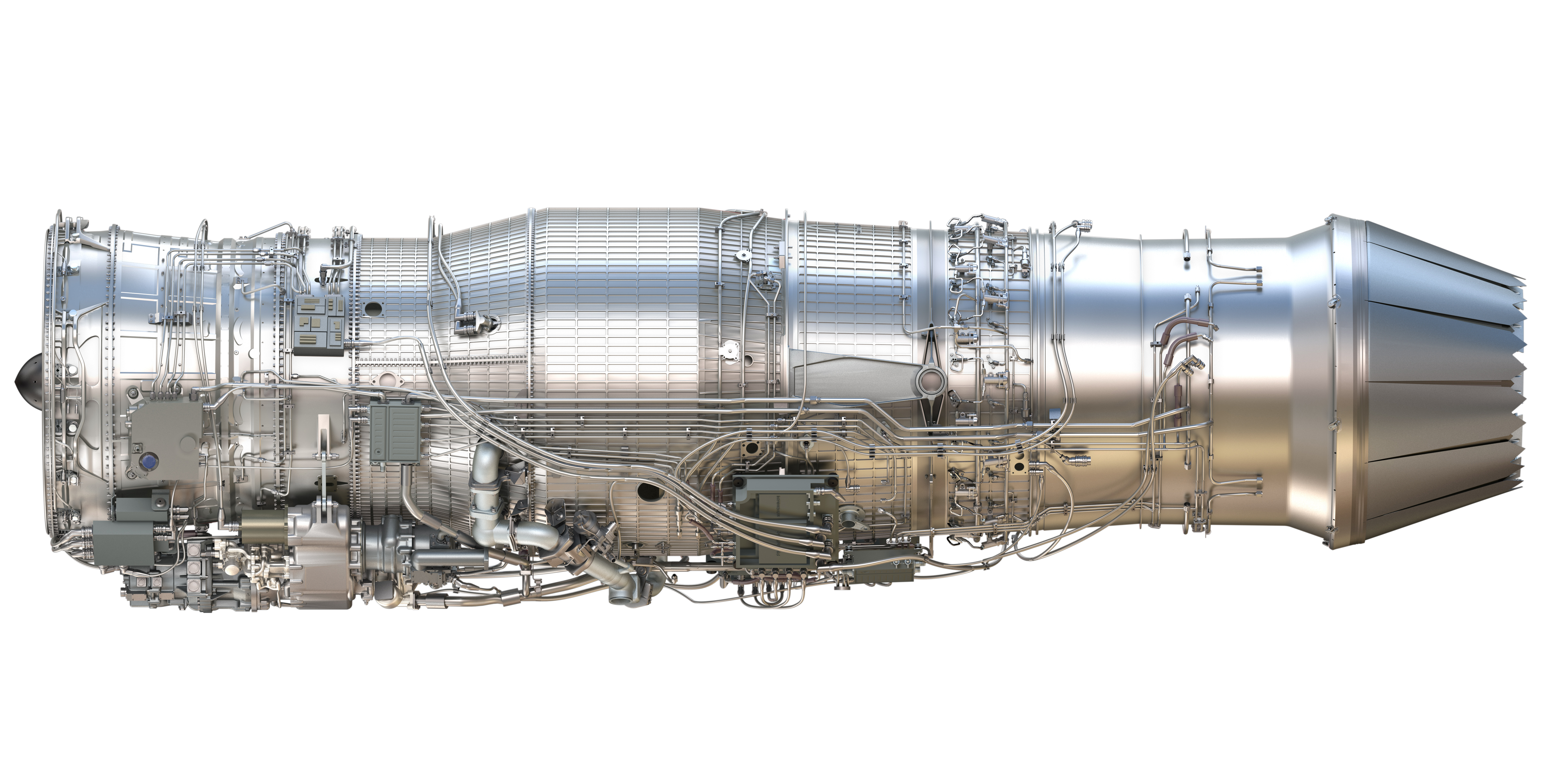

The ADVENT adaptive cycle engine holds some of the most advanced GE technology, including CMCs. Image credit: GE Aviation

People have been making things from iron and steel for more than 3,000 years. Machines built from their alloys have landed on the Moon and reached the very bottom of the ocean. But engineers like GE Aviation’s Sanjay Correa now believe that “we’re running out of headroom in metals.”

He and his team at GE say that a new class of materials called ceramic matrix composites (CMCs) is set to revolutionize everything from power generation to aviation, and allow engineers build much more powerful and efficient jet engines before the end of the decade. “This is a huge play for us,” Correa says.

Correa has an inside view. He leads GE Aviation’s CMC program and the company just announced that it would spend $200 million to build two new CMC factories in Huntsville, Ala.

The Rocket City factories -a nickname tied to Huntsville’s role in launching Americans to space – will be supplying raw material to the first American CMC plant, which GE opened last year in Asheville, NC.

The company also already operates two CMC “lean labs” in Newark, Del., and Cincinnati, Ohio, that are looking for new applications for the materials and new ways to make them. “Opening the new plants in Alabama is a key step in building up the supply chain we need to make CMC parts in large volumes,” Correa says.

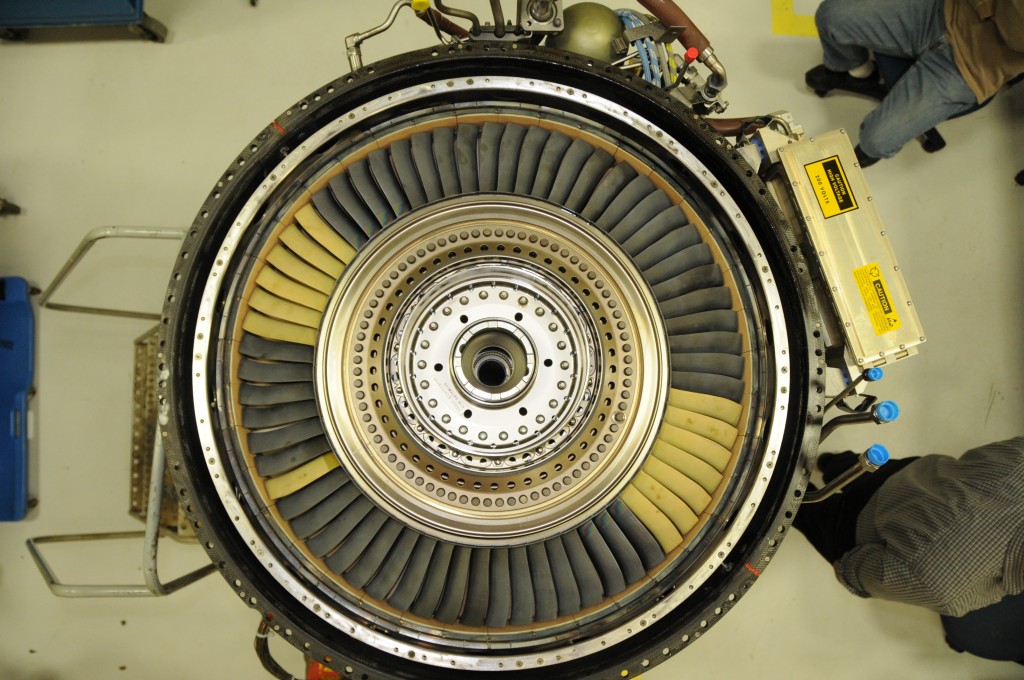

GE brought this jet engine turbine blade made from CMCs to the 2015 Paris Air Show. Image credit: GE Aviation

GE scientists have been working on CMCs for two decades. These “super ceramics” are as tough as metals, but they are also two-thirds lighter and can operate at 2,400 degrees Fahrenheit – 500 degrees higher than the most advanced alloys. This combination allows engineers to design lighter components for engines that don’t need as much cooling air, generate more power and burn less fuel.

Correa and his team believe that CMCs could allow designers to increase jet engine thrust by 25 percent and decrease fuel consumption by 10 percent by 2020.

While these numbers are pregnant with promise, CMCs have been extremely difficult to mass-produce. Until fairly recently, their use was limited to the space industry and fighter jet exhaust systems.

GE’s first applications were less lofty, but also more practical. Starting in 2000, GE’s Oil & Gas business tested CMCs inside a 2-megawatt gas turbine in Florence, Italy. By the middle of the decade, turbines with CMC shrouds – special parts directing the flow of air into the hottest parts of the machines – were running for thousands of hours without a hitch.

GE’s aviation business picked up the technology in 2007 and started looking for jet engine applications at its lean laboratory in Delaware. (This is an example of the vaunted “GE Store” – the transfer or technology and knowledge between GE businesses.)

GE is testing CMC parts inside engines for passenger planes as well as fighter jets. Image credit: GE Aviation

GE Aviation first used the material for CMC shrouds in the hot section of its F136 fighter jet engine, but their application quickly spread.

Static CMC parts are already flying inside the next-generation passenger LEAP engines developed by CFM International, a joint company between GE and France’s Snecma (Safran).

CFM has received more than 9,500 orders and commitments for the engines valued at more than $120 billion (list price).

In 2015, GE started testing CMC components in a GEnx engine – the type used by many Boeing Dreamliners – to mature the technology for its latest large engine: the GE9X.

When finished, the GE9X engine will be the largest jet engine ever built with 11 feet in fan diameter and capable of producing 60:1 air compression – arguably the highest ever in the history of aviation. “We expect a 10-fold increase in demand for CMCs when these and other engines take off by the end of 2020,” Correa says.

Correa’s team is far from finished, though. Earlier this year, they tested the first spinning parts inside the latest-generation ADVENT adaptive cycle engine, a demonstrator engine for the U.S. Department of Defense.

GE researchers have now started replacing rotating metal components with CMCs. This is big deal since shedding their weight by two thirds will produce a knock-one effect by lowering the centrifugal force inside the engine. For example, it will allow designers to reduce the size of the engine’s main shaft and cut engine weight further.

The ADVENT’s low pressure turbine with blades from CMCs. Some of them are covered with a special yellow environmental coating. Image credit: GE Aviation

As the name implies, composite materials like CMC are made from separate materials, which are then joined together. Concrete, for example, is a primitive but simple example of a composite.

GE makes CMCs from tiny silicon carbine fibers embedded in a silicon carbide matrix. The fibers are 5-times thinner than human hair and coated with a “very highly proprietary coating,” Correa says. The result is “tough like a metal [but] not brittle like a ceramic,” he says.

GE first started producing the fibers in Japan in 2012, after it formed a joint venture company, NGS Advanced Fibers Co., with Nippon Carbon and Safran. NGS owns one half of the company and the GE and Safran split the rest.

One of the new Huntsville plants will be first such facility in the U.S. It will supply GE businesses and also the U.S. Department of Defense. The second facility will take the fiber and make a highly-proprietary CMC tape for use by the GE CMC plant in Asheville.

The other two components of GE’s CMC ecosystem – the lean labs in Ohio and Delaware – are already looking for new applications for the materials and new fabrication methods, respectively.

Before long, you maybe flying to China in a plane powered by ceramics.

Filed Under: Materials • advanced