Solid brass one-piece water control valves are costly to manufacture because they require secondary machining to create complex flow paths. One of Minnesota Rubber and Plastics’ (MR&P) customers requested a new valve design to reduce casting costs and improve part function. The valve is a critical component for a water softener.

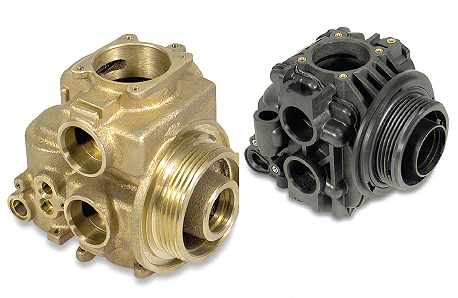

The water control valve for water softeners is cast from heavy brass and requires multiple precision machining operations. Right: The new molded assembly makes the part more lightweight.

MR&P took on the project and agreed to work with its customer to redesign the traditional brass control valve into a molded assembly with threaded inserts. The project involved a dual tank water treatment control valve that provides a continuous supply of softened water from one tank while a second tank is regenerated. The control valve is critical to reliable water softener function by regulating flow rates for resin regeneration, rinsing, and flushing the water softener. Measuring 5-in. x 3-3/4-in. x 5-in., the valve services both resin tanks in the water softener.

The design challenge for MR&P was to provide a molded water control valve equal to or better than the existing brass water control valve without sacrificing water flow rates while meeting regulatory requirements for structural performance and water purity. The project called for staying within budget and achieving material and energy savings with just-in-time delivery.

“We met those design requirements,” reports Ted Ahrenholtz, MR&P technical support manager. “We knew from the start that we would be able to reduce material usage, weight, and cost. Precision machined brass is expensive and heavy. Machining is slow, causes a lot of residual scrap, and the process requires significant energy consumption.”

The three-piece molded assembly is hot plate welded together for a water tight seal of the valve body. Many machining operations were eliminated by using a molded valve design.

The list of objectives included meeting flow requirements, generating a more aesthetic surface finish, reducing weight and cost, and speeding up turnaround time. The design teams used CAD, FEA, and SLA simulation software to design an assembly to replace the old version.

For this project, MR&P designed a three-part valve body configuration. The components were hot plate welded together. “Material selection for this project was important for improving part function, extending part lifecycle, and conserving material and energy needed to mold the components,” reports Ahrenholtz.

“We insured that rubber and plastic materials complemented each other’s tolerance capabilities and that there was a careful balance between the torque value and seal contacts. We used thermoplastic injection molding on the three plastic valve body components and transfer molding on the NSF 61-compliant, chloramine resistant rubber seals and O-rings. Through the use of FEA, the wall thickness was optimized, conserving plastic material while increasing overall valve strength with less weight and reduced total cost.”

Advantages of the new water control valve include: a 75% weight reduction, non-corrosive reinforced thermoplastic body, identical inlet and outlet plumbing connections as on the brass valve, along with leak and pressure testing of each welded valve prior to shipping.

Minnesota Rubber and Plastic

www.mnrubber.com

::Design World::

Filed Under: Hydraulic equipment + components, Valves, FLUID POWER, Materials • advanced

Tell Us What You Think!