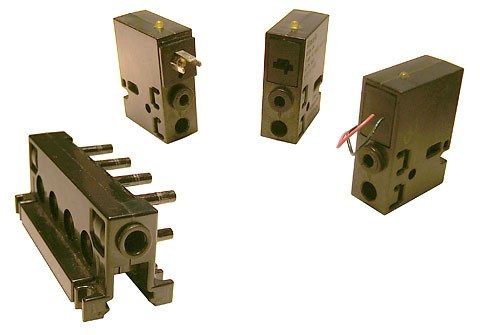

Isonic‚® 2, 3 and 4-Way valves feature a unique, multi-patented design that shrinks valve size while boosting flow capacity. Isonic‚® technology eliminates all machining operations associated with valve manufacturing. Requiring only simple assembly, Isonic‚® can be produced quickly and easily with significant cost reduction.

The heart of the Isonic‚® concept is its patented ‚“half-shell‚†design. Composed of two mirror-image halves, Isonic‚® allows its flow channels and internal component compartments to be designed directly into these molded body sections. Valve bodies are molded of high-strength, glass-impregnated Ultem thermoplastic.

Assembly is achieved by simply inserting the various valve elements into their corresponding ‚“half-shell‚†pockets. Internal components are easily positioned to make optimal use of space.

The valve is completed by ultrasonically welding the two valve segments, creating a strong bond and hermetic seal. This design totally eliminates the need for fasteners, adhesives, gaskets and inserts.

Along with its size and price advantages, Isonic‚® offers numerous user features, many of them standard. Most models feature an integral electronic board with surge suppression and LED. A variety of voltages and wiring options are available. This combination of price and versatility make Isonic‚® the perfect control choice for pneumatic systems.

Isonic‚® eliminates the need for tube fittings. Built-in, push-to-connect collets allow for fast and easy tube and manifold connections.

::Design World::

Filed Under: Pneumatic equipment + components, Valves, FLUID POWER

Tell Us What You Think!