Sponsored content | Chieftek Precision USA

Chieftek Precision USA supplies linear guides, direct-drive rotary tables, linear stages and motors, linear encoders, and servo drives to the industrial automation, machine tool, medical device, and laboratory industries.

The original focus of the manufacturer was on the design and manufacture of miniature linear guides. Today these precision linear offerings (including Chieftek miniature rail or MR series linear guides) continue to lead in all industries.

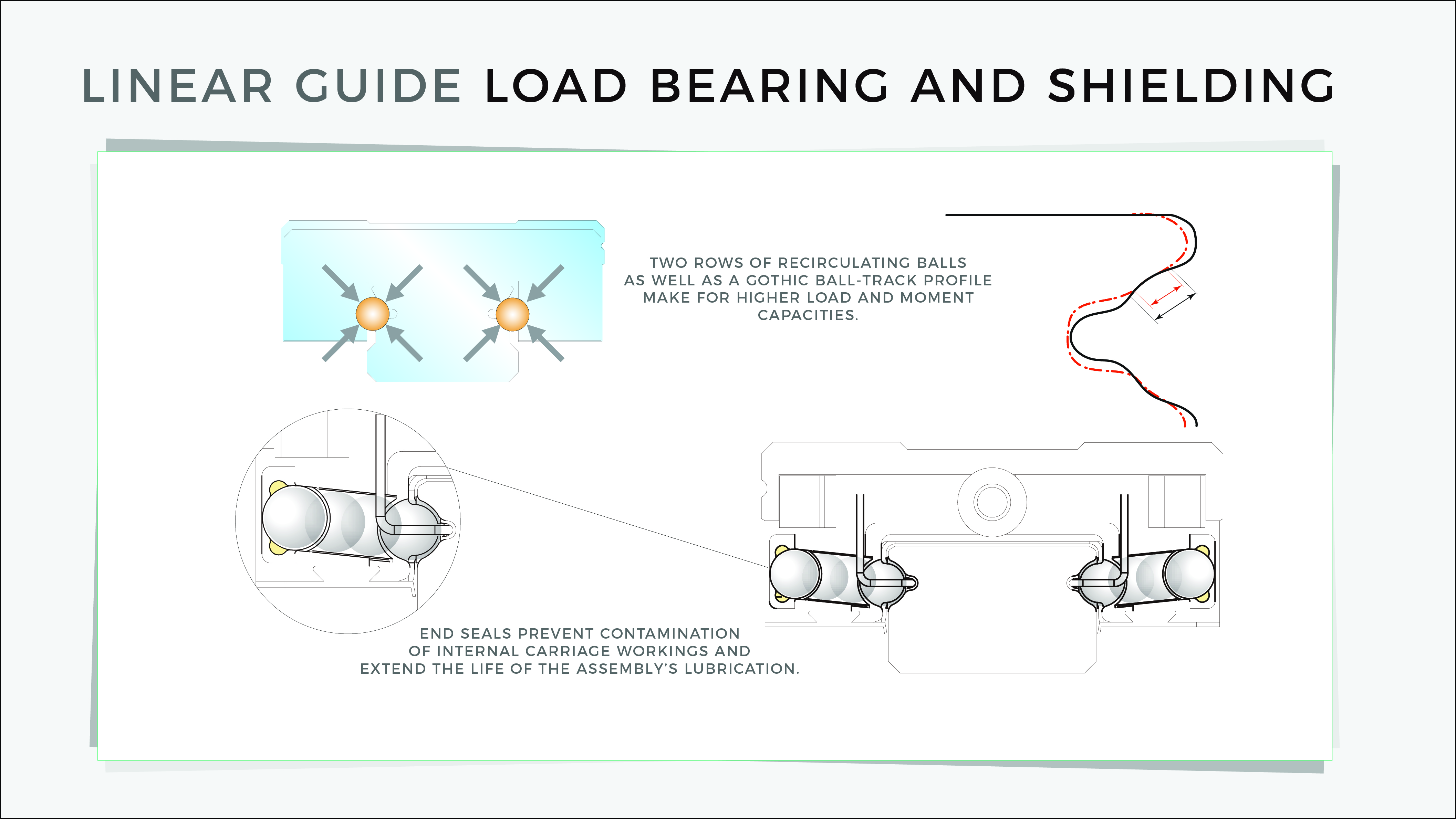

In addition to miniature guides, Chieftek slide and guide components for automated designs include four-row roller-type linear guides; wide and standard four-row ball-bearing linear guides; and ST miniature stroke slides with two rows of balls and a gothic ball track with 45° contact for high load capacity.

Chieftek linear slides include miniature guides — the manufacturer’s original component and perhaps the best-known miniature slide in the medical industry.

The linear guides operate in an array of applications — including pharmaceutical dispensers, blood-testing equipment, physical-therapy machines, airway-clearance devices, eye-surgery positioners, and other surgical and dental tools.

Consider just a few of the linear-guide options and design elements that improve automated designs.

Stainless steel for hygiene: Besides carbon steel (which is useful where cost control is an objective) miniatures slides from Chieftek also come in stainless steel. Such construction is indispensable in equipment that must remain hygienic and resist corrosion even when subject to caustic cleaning solutions (and maintain precision over the life of the machine). Chieftek offers stainless steel versions of its MR series as standard.

Shown here is a miniature linear guide from Chieftek on a screw-driven linear actuator.

Cleanliness with highly engineered sealing and lubrication solutions: The Chieftek MR series ZU-type carriage block has lubrication pads along with end seals and bottom seals. The latter can prevent lubrication grease from leaking from the runner block, which is key for equipment installed in cleanrooms or critical laboratory settings.

In addition, the lubrication pad conserves grease and extends the how long the guides can operate before needing relubrication.

In many Chieftek linear slides, a highly engineered ball-track geometry and multiple rows of balls boost overall load capacity.

Embedded inverse-hook design to let slides run faster: Recall that the rolling balls subject the linear-guide carriage endcaps (typically made of plastic) to impact during the directional changes they recirculate through the their path within the carriage block. Many Chieftek linear guides resolve the resulting impact forces with hooks to secure the block components and distribute the resulting stress over a wide area. In fact, Chieftek introduced this carriage feature to maximize the speed capabilities of its linear guides for automated equipment such as laboratory machines required to test large sample arrays. These linear guides complement high-speed axes actuated by belt drives and those on carriers and axes shuttling items between stations.

Durable end reinforcements protect blocks from external strikes and internal roller forces: Some linear slides from Chieftek integrate stainless-steel endplates on their carriage blocks. These outperform plastic endcaps where objects strike the linear guide’s carriage ends. Reinforcing endplates also increase allowable speed on otherwise equivalent designs — from 3 m/sec to 5 m/sec in some cases. With this feature, some linear guides achieve a maximum acceleration to 250 m/sec.

Chieftek UE series miniature linear bearings are one newer offering: MR-M SUE and ZUE linear guides have a bottom seal on the runner block and stainless-steel reinforcing endplates so the design is fast and rugged — and resists ingress of debris. ZUE guides are like SUE guides and include a built-in lubrication pad.

Manufacturer expertise to support customized builds: Chieftek engineers have extensive experience in the application of linear guides in a wide array of machine builds. That means they can make recommendations on an array of design options — factors such as the omission or inclusion of preload.

For example, Chieftek grades its miniature linear guides by preload level — V0 fit with positive clearance for smooth running; standard VS fit to balance precision and life; and V1 fit with modest preload to maximize axis vibration mitigation, rigidity, and load balancing — though with a design tradeoff of slightly more friction and wear and slightly reduced maximum acceleration. Extensive experience means that Chieftek offers design engineers ways to quantify the effects of this and a whole host of other design choices — and simplify optimization of linear designs.

Chieftek is the largest manufacturer of miniature linear guides in the world. For more information, visit chieftek.com.

Also be sure to download the Chieftek MR catalog as a PDF by clicking here.

You may also like:

Filed Under: Motors (linear), Encoders • linear, LINEAR MOTION, SPONSORED CONTENT