A new DC-source benchtop instrument aims to integrate the capabilities of I‑V systems, curve tracers, and semiconductor analyzers as used for characterizing wide bandgap power semiconductors such as SiC and GaN.

The Model 2460 SourceMeter Source Measure Unit (SMU) Instrument incorporates a capacitive touchscreen graphical user interface and can source up to 105-V, 7-A DC/7-A pulse, 100 W max. with 0.012% basic measurement accuracy and 6½-digit resolution. It can run four-quadrant voltage and current source/load measurements. Besides working with high-power semiconductors, the device is said to be well suited for characterizing elements of power conversion and management systems, such as solar cells/panels, new materials, and power management devices.

The instrument also finds use in electrochemistry applications where its high current output supports galvanic cycling of rechargeable batteries; its four-quadrant source and sink design makes it suitable for cyclic voltammetry with electrochemical cells. Its built-in control and display features also make the Model 2460 useful for characterizing electrochemical deposition, corrosion, and electroplating.

For characterizing optoelectronic devices like LEDs, OLEDs, HBLEDs, solid-state lighting, and laser diodes, the Model 2460’s 7-A DC capability provides enough current to run forward and reverse-bias I-V characterizations. The 7-A pulse current it provides minimizes device self-heating during leakage current testing.

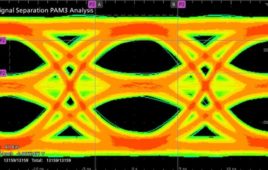

The instrument uses a full-color, five-inch touchscreen said to be designed for users who aren’t full-time test engineers. A full graphical plotting window converts raw data and displays it immediately as useful information, such as semiconductor I-V curves and voltammograms. The touchscreen supports “pinch and zoom” operation to allow examining data in the graph in detail.

Also included is a built-in context-sensitive help function through the touchscreen, minimizing the need to review a manual. Four single-touch Quickset modes simplify measurement setup without the need to configure the instrument indirectly for this operation. For complex analyses, data can be easily stored to disk, then exported to a spreadsheet. Up to four Model 2460s can be configured for multi-pin testing.

The Model 2460 is also engineered for integration into automated test systems via features such as Embedded Test Script Processor (TSP) Technology which embed test programs into non-volatile memory within the instrument itself rather than run it over GPIB/USB/LAN with an external PC controller. Through TSP multiple devices can run in parallel, with each instrument in the system able to run its own complete test sequence, creating a fully multi-threaded test environment.

A feature called TSP-Link Channel Expansion Bus lets test system builders connect multiple Model 2460s and other TSP instruments in a master-slave configuration that operates as one integrated system. The TSP-Link expansion bus supports up to 32 units per GPIB, USB, or IP address.

A triggering system called TriggerFlow lets users build triggering models ranging from very simple to complex with up to 255 block levels. The Model 2460 also includes basic triggering functions, including immediate, timer, and manual triggering.

A rear-panel mass termination connector and remote control interfaces (GPIB, USB 2.0, and LXI/Ethernet), D-sub 9-pin digital I/O port (for internal/external trigger signals and handler control), instrument interlock control, and TSP-Link jacks simplify the task of configuring multiple instruments and eliminate the need to invest in additional adapter accessories.

The Model 2460 is $7,500; a version without a front panel designed for integration into automated systems is available for $7,200.

Keithley Instruments, 28775 Aurora Road, Cleveland, OH 44139-1891, www.touchtestinvent.com, toll free 888-534-8453, 440-248-0400, FAX:440-248-6168

The post New DC source targets high-current device testing appeared first on Test & Measurement Tips.

Filed Under: Test & Measurement Tips