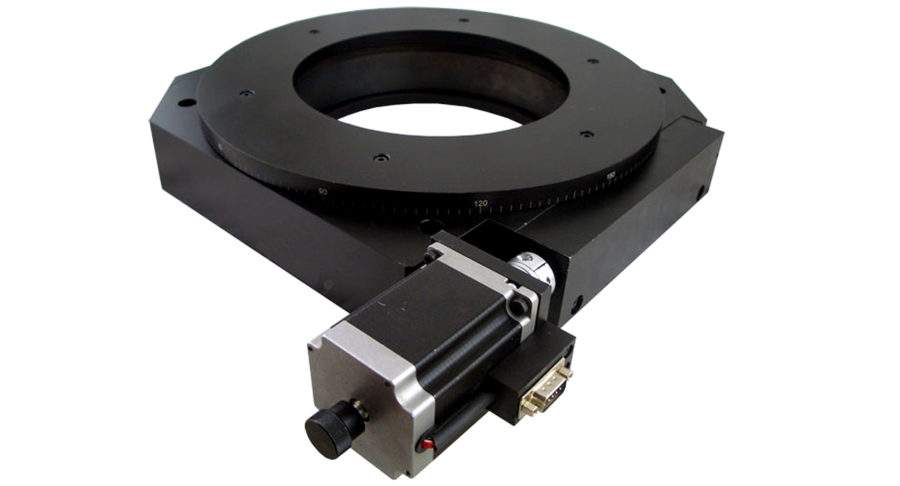

The new AY110-300 motorized rotary stage from Optimal Engineering Systems, Inc. (OES) features a large 180 mm (7.087 in.) open aperture. This precision, large open aperture (hollow core), low profile rotary stage is just 65 mm (2.559 in.) high and its foot print is 303 mm by 319 mm (11.929 in. by 12.559 in.) not including the motor.

The rotary table of the stage has a precise pattern of threaded holes for mounting custom tooling and fixtures, and holes in the base for easy integration into new and existing applications. The diameter of the rotary table is 300 mm (11.811 in.) and the range of travel is a full 360° and it is capable of continuous rotation. The table is driven by a smooth 288:1 worm gear and has a resolution of 0.000625o with a 10 micro-step per step stepper motor driver. The AY110-300 Rotary Stage is also available with a servo motor and optical encoder. The standard model is equipped with stepper motor and a knob for manual adjustment which can be replaced with an optical encoder for precision position verification.

The low cost, low profile AY110-300 Rotary Stage features a very low backlash of 0.0005o, and a positional accuracy of 0.001o, making it suitable for: Laser positioning and machining, scribing, microscopy, testing, assembly, inspection, alignment, and other critical applications. This black anodized stage has a load capacity of 65 kg (143 lb) and there’s an indicator scale for visual sighting of the angle of rotation. The stage can be ordered with Plug-and-Play with a fully compatible controller from OES.

Optimal Engineering Systems, Inc. (OES) is a manufacturer of motion control products including: Stepper motor controllers and drivers, solenoid electronics, and positioning stages and slides. Applications include: Animation, automated assembly systems, automation, CNC machines, flight simulation, inspection systems, linear and rotary stages, machine tools, medical devices, motion control camera boom systems, optical comparators, CMMs, pan-tilt gimbals, PCB assembly & inspection, pick-and-place, positioning stages, robotics, scanners, security cameras, telescope drive mechanisms, time-lapse photography and winders.

Some industries OES serves are aerospace, astronomy, chemical, communications, educational institutes, university, colleges, government agencies, national labs, manufacturing, medical, metrology, military, motion control, museum, news agencies, semiconductor and test equipment. Optimal Engineering Systems, Inc’s. competitive advantage is its state-of-the-art in-house manufacturing facility in North America enabling OES to supply clients with custom designed orders or high volume just-in-time deliveries globally. For more information, visit oesincorp.com.

Filed Under: FASTENING • JOINING • locks • latches • pins, Encoders • optical, Motors • stepper, Motion Control Tips

Tell Us What You Think!