Researchers at the Hebrew University of Jerusalem’s Center for Nanoscience and Nanotechnology have developed a new type of photoinitiator for three-dimensional (3-D) printing in water. These novel nanoparticles could allow for the creation of bio-friendly 3-D printed structures, further the development of biomedical accessories and drive progress in traditional industries such as plastics.

3-D printing has become an important tool for fabricating different organic based materials for a variety of industries. However, printing structures in water has always been challenging due to a lack of water soluble molecules known as photoinitiators—the molecules that induce chemical reactions necessary to form solid printed material by light.

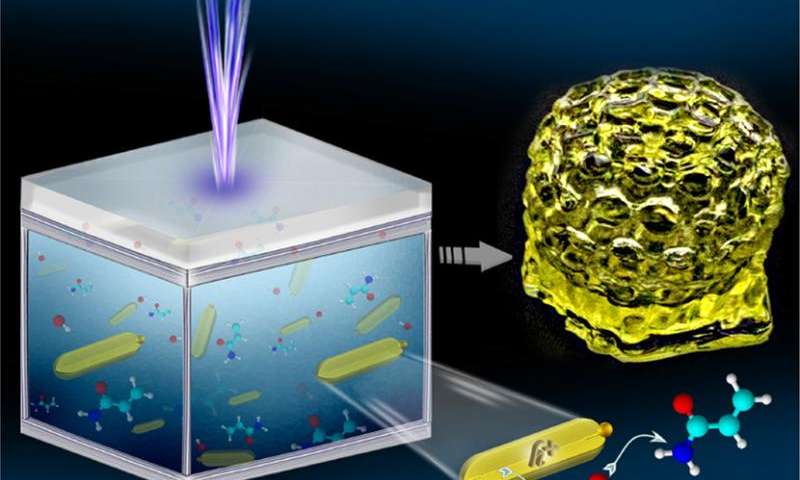

Now, writing in Nano Letters, Prof. Uri Banin and Prof. Shlomo Magdassi at the Hebrew University’s Institute of Chemistry describe an efficient means of 3-D printing in water using semiconductor-metal hybrid nanoparticles (HNPs) as the photoinitiators.

3-D printing in water opens exciting opportunities in the biomedical arena for tailored fabrication of medical devices and for printing scaffolds for tissue engineering. For example, the researchers envision personalized fabrication of joint replacements, bone plates, heart valves, artificial tendons and ligaments, and other artificial organ replacements.

3-D printing in water also offers an environmentally friendly approach to additive manufacturing, which could replace the current technology of printing in organic based inks.

Unlike regular photoinitiators, the novel hybrid nanoparticles developed by Prof. Banin and Prof. Magdassi present tunable properties, wide excitation window in the UV and visible range, high light sensitivity, and function by a unique photocatalytic mechanism that increases printing efficiency while reducing the amount of materials required to create the final product. The whole process can also be used in advanced polymerization modalities, such as two photon printers, which allows it to produce high resolution features.

Hybrid nanoparticles as photoinitiators. a. Electron microscope image of hybrid nanocrystal. The inset shows a schematic of semiconductor nanorod with a metal tip. b. Bucky ball structure produced by rapid 3D printing in water using HNPs as photoinitiators. c. Spiral printed with HNPs by two photon printer providing high resolution features. (Image Credit: Pawar et al)

Filed Under: M2M (machine to machine)