Thermal transfer is a key element of efficient anaerobic digestion (AD) plants. Whether pre-treating or pre-heating feedstocks, improving process efficiency, or treating digestate to pasteurize it or reduce its volume, an increasing number of AD plant designers and operators are using heat exchangers to boost their thermal processing requirements. Yet, with such a variety of applications possible, it is important that you select the right heat exchanger for your individual requirement.

Know your process

There are a number of types of heat exchanger on the market: plate, tubular, corrugated tube, scraped surface, etc. Each is suited to a particular application, so think carefully about your process, including the nature of the material/s to be heated or cooled, the objective of the process (such as pre-heating or pasteurization) and any restrictions of the environment where the heat exchanger is to be used. The driving force for heat transfer is the difference in temperature between the two substances (in most cases fluids). In the case of a smooth tubular heat exchanger, the temperature of two simple fluids changes as they pass through the heat exchanger. One of the reasons for making corrugated tube and scraped surface heat exchangers is that they are suitable for fluids and materials with complex properties, such as viscous and non-Newtonian fluids, or for materials containing particles or sediment. You should therefore always be mindful of the material to be processed before selecting your heat exchanger and it’s a good idea to seek professional advice from manufacturers and their agents, to help with the selection process.

One size does not fit all

Once the correct type of exchanger has been chosen, developers and operators must then make sure that the model supplied is correctly sized for the job. In other words, that it offers the right amount of heat transfer for the fluid/s being treated and at the throughput required. The heat exchanger must have a large enough heat transfer area for the specified fluids and their specified inlet and outlet temperatures. Most calculations should also factor in variables such as whether the heat exchanger operates using counter-flow or parallel flow.

Breaking down barriers

Another important factor controlling heat transfer is the resistance to heat flow through the various ‘layers’ that form a barrier between the two fluids. There are effectively five of these layers:

- The inside ‘boundary layer’ formed by the fluid flowing in close contact with the inside surface of the tube.

- The fouling layer formed by deposition of solids or semi-solids on the inside surface of the tube (this layer may or may not be present, but is particularly found with digestate).

- The thickness of the tube wall and the material used, which will govern the resistance to heat flow though the tube itself.

- The fouling layer formed by deposition of solids or semi-solids on the outside surface of the tube (which may or may not be present).

- The outside ‘boundary layer’ formed by the fluid flowing in close contact with the outside surface of the tube.

The values for numbers 2 and 4 can usually be supplied by the client based on experience, while the designer of the heat exchanger will select the tube size, thickness and materials to suit the application. The resistance to heat flow resulting from numbers 1 and 5 (known as the partial heat transfer coefficients) depends both on the nature of the fluids and the geometry of the heat transfer surfaces themselves.

Creating turbulence

One way to prevent the build-up of these layers is to increase the speed at which the fluid passes through the heat exchanger so that turbulence is formed and the boundary layer breaks away from the surface of the tube. This is the point at which so-called laminar flow (with the fluid passing through in smooth layers, where the innermost layer flows at a higher rate than the outermost) becomes turbulent flow (where fluid does not flow in smooth layers but is mixed or agitated as it flows).

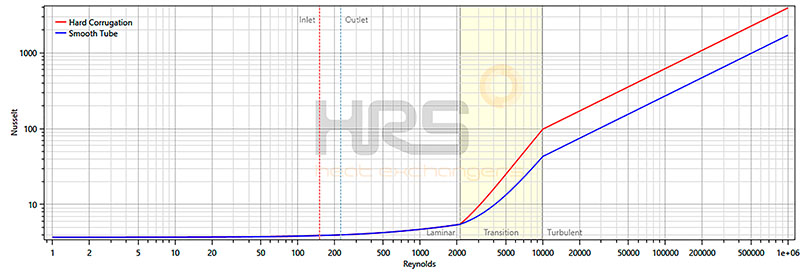

The speed at which this occurs is influenced by many different factors, but in order to quantify it for the purpose of specifying heat exchangers, engineers use something called the Reynolds number (Re). This is determined by the diameter of the tube, the mass velocity of the fluid and its viscosity. Reynolds numbers of less than 2,100 describe laminar flows, while numbers above 10,000 describe full turbulent flow. Between the two values is an area of uncertainty called the transitional zone, where we see a general transition from full laminar to full turbulent flow. In practice, engineers try to provide solutions outside of this zone as much as possible. Tube deformation such as corrugation helps to increase the heat transfer performance once the fluid/s have entered the turbulent flow area (Re > 2,100). This is the main reason for using corrugated tube heat exchangers.

Determining when laminar flow becomes turbulent flow is critical to equipment performance

State of the art calculations

As with any kind of science, the mathematics and understanding of thermal dynamics is continuing to evolve and improve. However, much of the literature commonly used to build calculations and model heat exchanger performance can be up to 80 years old, and does not always reflect the most recent science. Also, while there is scientific literature for the behavior of fluids in smooth and corrugated tubes, there is little published data on scraped surface heat exchangers.

Using its experience, and the most recent scientific data available, HRS Heat Exchangers has produced a new state of the art software program which we use to calculate the necessary size of our heat exchangers. It is already producing some interesting results and giving new insights into how to design tubular and scraped surface heat exchangers which provide the very best levels of performance.

The patented HRS UNICUS Series scrape surface heat exchanger handles difficult heat transfer applications efficiently

Filed Under: Rapid prototyping