SKF sealing solutions for industrial rotating equipment offer ideal solutions to retain lubricant and block harsh contaminants from adversely impacting asset performance and reliability. SKF Large Diameter Seals can be delivered in a wide range of styles, configurations, and materials to accommodate the most demanding speeds, temperatures, pressures, and environmental conditions. They especially can withstand the severe operating challenges typically encountered in the steel, pulp and paper, and mining industries, among many others.

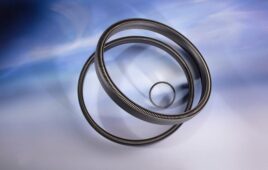

SKF Large Diameter Seals can be supplied in a variety of designs to satisfy particular industry applications. Standard designs include metal-cased outside diameters, rubber-cased outside diameters, and all-rubber types both in spilt and solid styles.

SKF can supply the best sealing profile based on the application requirements with noteworthy design features, including integrated spring combinations to provide optimal interference for long life and compensate for severe operating conditions, springless profiles to aggressively pump away contaminants, integrated PTFE-excluding elements for dusty and abrasive particle exclusion, and V-ring seal styles for mounting directly on the shaft and creating additional barriers against external contamination.

SKF Large Diameter Seals for heavy-duty industrial applications can be manufactured in virtually any size shaft diameter greater than 4 in. (102mm) and are engineered for optimized performance. Custom solutions can be developed to meet particular application requirements and delivered in 3-4 weeks with 24-hour turnaround available in cases of critical outages.

SKF

www.skf.com

Filed Under: Seals • O rings, Seals

Tell Us What You Think!