Adhesive systems routinely have to accommodate service temperature variations, but this thermal versatility sometimes comes at the expense of bond strength, chemical resistance or ease-of-use. Not so with Master Bond Supreme 10HTFL.

This one-component epoxy-based sealant and coating features an exceptionally wide service temperature range of 4 K to 350 °F. And it creates strong, tough bonds across that entire range. When bonding aluminum, for example, Supreme 10HTFL offers tensile lap shear strengths exceeding 2,000 psi and T-peels in excess of 40 pli.

As a flexible epoxy compound, it offers superior resistance to impact, thermal shock, vibration and stress-fatigue cracking. When combined with the wide service temperature range, this flexibility makes Supreme 10HTFL particularly well suited to thermal cycling applications. “Its performance properties are at their most impressive when bonding substrates with wide differences in their thermal expansion coefficients,” says Robert Michaels, Master Bond’s Vice President of Technical Sales.

Supreme 10HTFL also offers other desirable properties that are typical of high- performance epoxies. For example, it has superior chemical resistance to water, salts, oils, fuels and many organic solvents. It is also resistant to creep and will function as an electrical insulator.

Thanks to its unique balance of thermal and mechanical properties, Supreme 10HTFL has been applied as both an adhesive and as a sealant in demanding aerospace, electronic, electrical, computer, metalworking, appliance and chemical processing applications. It bonds readily to a variety substrates–including aluminum, steel, engineering thermoplastics, fiber reinforced composites, ceramics, glass, wood and many more.

Like other one-component epoxies, Supreme 10HTFL does require an elevated temperature and contact pressure to cure properly. Typical curing conditions are 75-90 minutes at 250°F or 45-60 minutes at 300°F for maximum bond strength. Even faster cures can be obtained at higher temperatures.

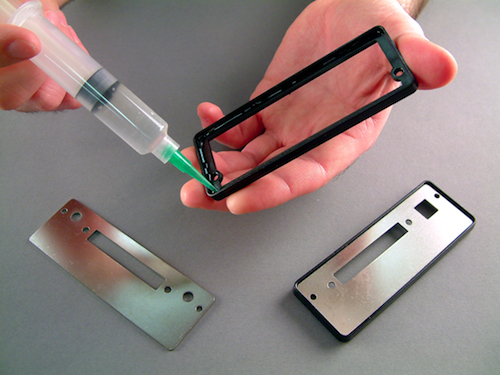

Aside from the need for some heat, using Supreme 10HTFL could not be simpler. It requires no mixing, has a consistent viscosity over time and stores at room temperature. Because Master Bond Supreme 10HTFL is 100% reactive and contains no solvents or diluents, shrinkage on cure is negligible.

Master Bond

www.masterbond.com

::Design World::

Filed Under: Adhesives • epoxies, Materials • advanced

Tell Us What You Think!