Jay Tedeschi is the Senior Solutions Evangelist of the Manufacturing Solutions Division, Autodesk

One hundred twenty-five conceptual designers. A handful of engineers. Thousands of decision-makers. Seventy-two hours to take their input from idea to physical prototype in a trade show exhibit booth. Was this a trade-show stunt or factory of the future?

Inventor Ben Kaufman pulled off this collaborative feat at the MacWorld trade show in 2007. Outrageous or visionary, the exercise suggests the challenge of managing input and development concurrently-albeit under extreme circumstances.

For Kaufman, data flow was crucial to meeting his deadline. For more sophisticated manufacturing operations, seamless data flow is vital to understanding the aesthetics and performance of design ideas.

In its 2007 benchmarking study on digital prototyping, Aberdeen Research reported that top-performing manufacturers rely on a digital pipeline to ensure the flow of information. This pipeline is a metaphor for a process and/or technology that enables project teams to share aesthetic and engineering information in a single digital model.

This digital pipeline must allow information to flow freely, without creating a situation where too much or too little information circulates. It must complement the design, engineering and manufacturing teams’ workflows, not inhibit them. Kaufman’s project hints at the potential for too much information and input to overwhelm team members. Too little, and team members may be inclined to fall back into using familiar but inefficient workflows-and the organization may not get the full benefit of digital prototyping.

Technology supports data flow

One way that technology supports data flow is by enabling digital communication. Aberdeen Research found that digital prototyping requires more than an e-mail system to communicate design and manufacturing information. Indeed, interoperability is the Holy Grail, and some software applications can exchange data directly with one another.

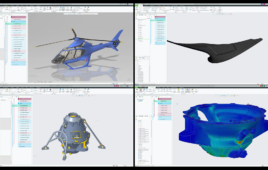

An image representing a videogame controller design provides enough information for the industrial designer (a), excluding wiring and electrical-connection features (b) and other design data not needed for the packaging design.

But you don’t need applications to exchange data indiscriminately. For example, an industrial designer working on a consumer product is most likely concerned with the physical characteristics of the mechanical assembly to be packaged. An up-to-date package “envelope” delivers that information, without burdening the designer with unneeded wiring or electrical specifications.

New technology provides options and opportunities in the way that we tackle design problems. However, it can also represent and introduce obstacles. Ultimately, we find ways to work together that can circumvent each team’s design application’s ability or inability to “talk” or share data with another application.

We’re still following an age-old master process: We still transmit ideas via drawings, albeit digitally, but the basic principle is the same as it has been for the last century or so. Unfortunately, a drawing captures only design, not intent, and to this day, the designer or design team’s intent remains for the most part in someone’s head. This mode of communication that was established thousands of years ago didn’t include collaboration.

Technology offers a step toward collaboration

While applications may not “talk” to one another directly and people may not communicate clearly, technology is improving our ability to work together.

Aberdeen found top-performing manufacturers documented engineering deliverables electronically and early on, making them “portable” across divisions. As I talk with manufacturers, I’m seeing progress of this kind in their use of document-management tools.

First and foremost, these tools employ powerful database engines, and let you perform sophisticated searches of both design and design-related information. Used in this fashion, they offer tremendous value as they let you capture collective design intelligence and intent. This is significant, as pockets of knowledge now can be leveraged by the entire design team. It seems every engineering team has at least one person—usually a long-time employee—who has encyclopedic knowledge of the team’s specific design and manufacturing nuances. Everyone typically turns to this person with all of those questions that—were it not for this individual-would require a physical prototype to validate size, dimensional and structural properties, plus other types of data.

Document-management tools allow teams to capture the information that resides in that expert’s head and enable rapid searching and cross referencing of that information. New, easy-to-use products are replacing difficult-to-implement, costly ones. Engineers can use these tools to find the features that successful designs share in common and build on those proven elements. Project managers can search progress with respect to timeline, deliverables or project milestones.

Controller mold-flow-analysis image assists manufacturing engineering in optimizing mold base characteristics.

Collaboration is important, because Digital Prototyping is not a linear process

Consider a console gaming controller. Initially independent, concurrent areas of activity like industrial, electrical and mechanical engineering tasks quickly become interdependent. Structural and electrical aspects of the controller that are initially designed, analyzed and evaluated by their respective teams then have to be connected through wiring and physical interfaces, which in turn must be analyzed and refined.

Collaboration is needed between the electrical, mechanical and industrial design teams. For example, design engineers may work closely with manufacturing in defining the location of mounting bosses and support ribbing to ensure that the mold for the plastic housing yields the best possible results. They seek to minimize the quantity of materials used and maximize the number of units produced by optimizing the speed with which they can be formed, cooled and released from the mold.

At the same time, the electrical design team needs standoffs to be incorporated into that mold design—and they need them to be threaded to allow for the mounting of the printed wiring board, as well as other components. As certain design milestones are met, the mechanical design team needs to alert the electrical design team that the space available for wiring or the circuit board is now well-defined in the design, and they should prepare to finalize the printed wiring board that will go into that space.

If each team is following the key principles of a Digital Prototyping workflow, then each is generating models that integrate geometry and performance data to simulate function. And of course, these in turn need to be integrated into a single model for each team’s use.

Data-management system is the master conduit

Many ways exist to bring form and function together, using a variety of tools, from software that links thermal or fatigue analysis to a structural simulation, or CAD software that supports behavior-based assembly modeling. For our console game controller, visual, dimensional, textural, spatial, thermal and other information needs to be represented.

Since technology may not be as interoperable as we’d like, the integration of all of these characteristics into a single model still requires collaboration among team members.

That’s the realm of document-management software. Today’s systems offer you a measure of flexibility—and control—over what may be shared and how, according to job function. These task-based degrees of sharing generally fall into some use-case categories.

Document management software can help streamline production of assembly instructions for manufacturing.

• Search and reuse: For those of you who need to easily locate files and ensure version control. You may need to just check-in/check-out capabilities at your desk to make sure that two people aren’t working on the same file at the same time. A “Uses/Where Used” capability gives you the tools needed to find where specific files and items (CAD and non-CAD) have been used across multiple assemblies, drawings and bills-of-materials (BOMs).

• Change management: Shortens change and release processes to have a positive impact on product-development process. These tools automate team notification, helping to reduce cycle time and improve the communication of crucial digital knowledge. Release management ensures that a design change triggers an engineering change order (ECO) process, routing the ECO automatically to decision-makers for review, change and approval. Formal release procedures create a historical record and capture design revision history. Typically, custom revision schemes may be used to configure the design data history.

• Project management: For the expanded team to be able to share information without technical or infrastructure constraints. Assembly instructions, generated by design engineering may be pushed to the shop floor where final assembly takes place.

Collaboration needs to extend to end users or consumers, as well. Customer feedback can be stored in the document-management system, where it’s available to multiple design disciplines. Information about product improvements and failures can be used by different design and engineering functions within an organization. Industrial designers can take customer feedback and tailor future designs and product revisions to be more in line with what customers want. Similarly, engineering can look for trends with regard to product failures, and use digital prototyping to examine more closely the high-stress areas as well as other aspects of performance for subsequent designs.

Likewise, the customer satisfaction feedback that goes to the industrial design team is available to the engineering and manufacturing teams, as well. Instead of relying solely on product marketing staff to collate that information, it’s readily accessible.

Inventor Kaufman’s online collaborative, Kluster, is somewhat primitive, but it hints at the power of optimized data flow. His live MacWorld fabrication project produced a physical prototype of the winning idea in 72 hours: the Bevy, an iPod case that’s also a bottle opener and key ring. He went on to sell 40,000 of these devices in 28 countries.

Autodesk

www.usa.autodesk.com/digitalprototyping

Filed Under: Software • 3D CAD, Digital manufacturing

Tell Us What You Think!