A new online electric actuator-sizing program from Tolomatic simplifies the design and specification of electric motion control projects. The online software allows precise specification of either rod-style or rodless electric actuators based on the motion profile (velocity/acceleration), orientation, loads and forces. Application and sizing details can be saved, printed and shared electronically with other design team members.

The sizing software uses a simple six-step process that includes defining the workload, establishing motions, matching an actuator, selecting a motor, adding features such as mounts or switches and viewing the results. The reporting tool allows the selection of final results to include all or selected aspects of the project parameters, along with a 3D CAD file of the selected actuator.

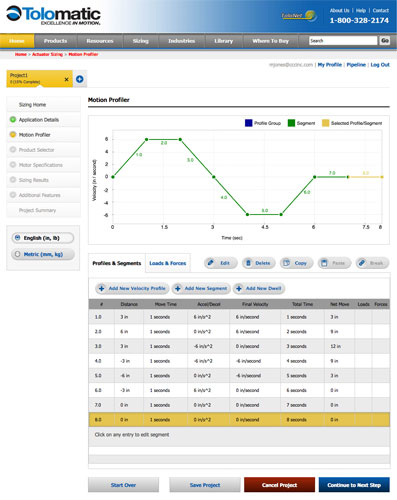

In the motion profiler section of the program, designers can enter specifics such as length of move; move time, acceleration/deceleration, final velocity and total time. In addition, the designer can enter loads to be carried or external forces that will be applied to the actuator. The resulting motion profile is displayed on a graph, and multiple motion segments, loads or forces can be added as necessary. The sizing software will then suggest and rank actuator products that best fit the application with respect to several parameters, one being most economical. Once the actuator product has been chosen, the designer can select various accessories such as mounting options and switches to build a complete part number for the desired actuator solution.

The last step in the process is to review the results or project summary. The designer can choose from a variety of reports including a full sizing report, motion control charts, loads/forces/moments or a motor specifications summary. Additionally, links to Tolomatic’s online product catalog and 3D model builder can be easily emailed and shared with others.

Tolomatic

www.tolomatic.com

Filed Under: Actuators, Hose • wraps + sleeves, Green engineering • renewable energy • sustainability, ENGINEERING SOFTWARE, LINEAR MOTION