Mating screw applications that require secure attachments can rely on self-clinching locknuts, which self-lock threads to reduce loosening and can be removed repeatedly without affecting performance.

By Michael J. Rossi, Marketing Services Supervisor, PennEngineering

By all measures, the hardware specified to attach components is expected to perform reliably in service. But sometimes application-related factors — vibration, thermal cycling, or other disruptive forces — will place fasteners in jeopardy. Especially in the case of mating screws, such forces can loosen them and potentially result in attachment failure. How can designers prevent such problems?

Self-clinching prevailing torque locknuts integrate a nylon hexagonal element offered as a locking mechanism option.

Self-clinching locknuts offer solutions on multiple fronts. They effectively “self-lock” the threads of mating screws to eliminate any risk of screws loosening over time, regardless of application forces. In addition, the locknuts allow for repeated screw removal and re-attachment without compromising thread-locking performance. And, unlike chemical locking methods or patches, locknuts do not require extra production steps and/or materials during the assembly process, saving time and money along the way.

Beyond their central function of withstanding external forces and holding mating hardware securely, self-clinching locknuts offer yet another layer of reliability, thanks to self-clinching technology. Upon their installation, the locknuts become permanent and integral parts of a thin metal assembly, will not loosen or fall out, never have to be restrained from rotation with a tool, and never have to be handled again.

Specific types of self-clinching locknuts further offer specific benefits, based on design. Some integrate floating threads to compensate for misalignment; miniature versions feature smaller footprints accommodating smaller design envelopes; and others will achieve particularly high clamp strength. The universe of self-clinching locknuts continues to expand in response to application and marketplace needs.

Locking mechanisms

When evaluating self-clinching locknuts for an application, designers can begin to narrow the field by considering two main categories: prevailing torque locknuts (in many variations) and free-running types.

Self-clinching prevailing torque locknuts encompass all-metal styles as well as locknuts integrating plastic inserts (usually nylon).

All-metal types “self-lock” the threads of mating hardware by fundamentally altering the shape of the nut during manufacture to grip a screw during tightening. A common method is the purposeful distortion of the nut’s threads. Depending on type, the nut’s threads may be elliptically squeezed (slightly deforming the thread barrel into an elliptical shape), flexing jaws may be created by vertically slitting the thread barrel and squeezing the two sections together, or one or two of the last threads on the head side of the nut may be deformed.

The particular design feature of all-metal prevailing torque locknuts produces friction between threads of mated hardware, thereby increasing the force needed to tighten as well as loosen the nut. Prevailing torque locknuts maintain essentially the same torque value, regardless of the amount of axial load applied, and have been engineered to provide up to 15 cycles of thread-locking performance.

Self-clinching free-running locknuts designed with a modified thread angle provide a vibration-locking feature.

Self-clinching prevailing torque locknuts with nylon inserts generate torque resistance using a plastic insert as the locking element.

The insert is added during manufacture into the self-clinching body of the nut on the screw exit side (with the inner diameter of the insert approximately at the screw pitch diameter). As the screw enters the insert, the resulting interference at the major diameter creates prevailing torque. A major advantage of this locking method is the ability to significantly reduce the chance of conductive debris forming from the repeated removal and re-installation of a screw. These, too, can offer up to 15 cycles of thread-locking performance.

In contrast to prevailing torque types, all-metal self-clinching free-running locknuts will require tightening against a bearing surface for the locking mechanism to function.

A modified thread formation on the loaded flank of these fasteners provides the vibration-resistant locking feature and allows mating screws to spin freely during the attachment process until clamp load is induced during the screw-tightening process. The applied clamp load then engages the locknut’s vibration-resistant locking feature, which locks the mating screw in place. (If the clamp load, is removed for any reason, the nuts no longer will provide any torsional resistance to rotation.) Locking feature reusability will be unaffected by the number of on/off cycles.

Regardless of locknut type, designers should always consider the potential impact of certain application conditions in realizing optimized performance of locknuts in service. As one example, locking features may be subject to temperature limits. Locknuts with nylon inserts generally have a recommended temperature limit of 250˚F (or 120˚C) before the strength of the locking feature will be affected. In turn, all-metal locknuts can usually be heated to higher temperatures without affecting the locking strength, but higher temperatures may give rise to brittleness and reduced corrosion resistance.

Permanent clinching

Self-clinching technology provides a big assist in the world of fasteners, in general, and locknuts, in particular. Self-clinching fasteners in all their many types and variations provide permanent and reusable load-bearing threads to accept mating hardware in ductile metal sheets too thin to be tapped or where extruded or stamped threads would be impractical.

Among other benefits, they allow for component removal and re-attachment whenever needed for access or service and can dramatically reduce or eliminate the amount of required attachment hardware. Fewer parts promote lighter designs and less hardware in an assembly translates to savings in product time and costs.

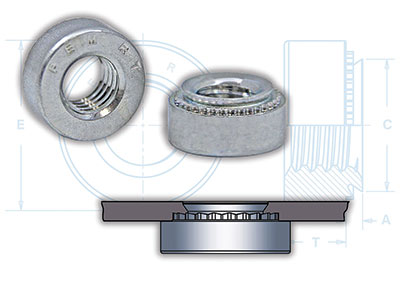

Self-clinching fasteners install easily (usually during the fabrication process) by pressing them into a properly sized hole and then applying sufficient squeezing force using a press. This process causes displaced metal sheet material to cold flow into an annular recess in the shank or pilot of the fastener, permanently locking the fastener in place in the assembly. A knurl or similar feature prevents the fastener from rotating in the metal when tightening torque is applied to mating hardware, such as screws in the case of locknuts.

Unique engineering

Self-clinching prevailing torque locknuts with a specially engineered “TRI-DENT” locking feature offer a cost-effective locking solution.

Each application will be characterized by distinct requirements and, within the overall family of self-clinching locknuts, uniquely engineered options can be specified to meet the challenges.

Profiles of three (among many) individual types of self-clinching locknuts for thin metal assemblies illustrate the range and capabilities.

Locknuts with “flexing jaws” embody a design particularly appropriate for severe service applications. These fasteners utilize two rugged, semicircular flexing jaws (instead of several less-supported segments) to achieve greater retention for preventing relaxation and loosening of the fastener over time. The design further protects the threads of a mating screw: clearances obtained by only two interruptions of a full circumference — together with the spreading of the jaws by the entering screw — will minimize the possibility of thread damage. A shoulder additionally provides increased pull-through performance and a positive stop during installation. The flexing action of their locking feature serves to permit repeated use and effective locking torque.

Locknuts with floating threads permit up to 0.030 in. or 0.76 mm adjustment for mating hole misalignment. Extra strength and support in the assembly is obtained by the threads of the floating nut extending into the fastener’s retainer shank.

Miniature locknuts are relatively lightweight with a smaller footprint and can be specified in a range of especially small thread sizes — making them ideal in applications where size and weight matter. A strong knurled collar, which becomes embedded when installed in a host metal sheet, guarantees against rotation of the fasteners in the sheet. The torque-out resistance of the knurl greatly exceeds the torque that can be exerted by the self-locking feature.

As these examples illustrate, self-clinching locknuts have been designed for virtually any application where securing a mating screw is mandatory. As a best practice, decision-making to identify the proper locknut type for an application can be reinforced by enlisting a supplier’s in-house technical and engineering resources early in the design stage. The support ultimately can contribute to locking in reliable application outcomes.

PennEngineering

pemnet.com

Filed Under: FASTENING • JOINING • locks • latches • pins, MOTION CONTROL