W. L. Gore & Associates has introduced the High WEP Series: a versatile venting solution to the increasingly stringent reliability requirements faced by design engineers and manufacturers of automotive electrical/electronic modules (EEMs).

Increasingly, EEMs require greater thermal, mechanical and chemical reliability. As electronic devices are mounted closer to the point of use, they are exposed to harsher operating environments and chemical contaminants. The miniaturization trend creates added challenges for weight reduction, component density and thermal management. At the same time, extended OEM warranty periods demand corresponding increases in EEM reliability and life-expectancy. The new High WEP Series addresses these global automotive trends that are re-shaping the requirements for EEM design, durability, and longevity.

Compared to other GORE® Automotive Vents for weldable installation, the new High WEP Series delivers nearly double the Water Entry Pressure (WEP) resistance. It achieves this impressive level of ingress protection without sacrificing either airflow performance or temperature resistance in the process.

A Versatile Solution to Multiple Challenges

Designed for ultrasonic welding, Gore’s new High WEP Series is engineered specifically for smaller, more densely configured enclosures in rugged automotive environments, particularly for exterior-mounted EEMs. Accordingly, the High WEP Series can deliver airflow performance that equals that of larger vents.

The High WEP Series has a minimum WEP of > 110 kPa at a hold time of 300 seconds.

This makes it highly effective at blocking ingress of water – not just during sprays and splashes, but even during “deep water wading” events. In addition, its chemically-resistant GORE™ Membrane of 100% ePTFE provides lasting hydrophobic and oleophobic protection, even when exposed to brake or other automotive fluids.

Even in harsh environments, this GORE™ Membrane maintains high roll-off properties, helping to ensure that water and other automotive fluids do not block the vent and inhibit pressure equalization. Depending upon individual housing design, these High WEP vents can enable EEMs to achieve protection levels from IP6K1 up to IP6K9K (ISO 20653).

The WEP/Airflow ratio is equally impressive.

While providing nearly double the WEP resistance, the High WEP Series maintains minimum airflow of 15 l/h/cm2 at 7 kPa. This ensures rapid, reliable equalization of pressure differentials and release of heat buildup. At the same time, reduction of condensation is effectively supported, which is essential to keep sensors and other EEMs delivering precise and accurate data. EEMs that required a larger vent to achieve desired venting performance can now reach the same performance targets with a smaller High WEP vent.

Gore’s High WEP Series also provides temperature stability from -40 °C to +150 °C.

While this exceeds prevailing standards, many under-hood applications – such as actuators for turbocharger flaps or exhaust gas recuperation valves – currently require this level of temperature resistance to reliably withstand normal operating conditions.

For motors, sensors, control units, actuators and other sensitive EEMs, the low-profile High WEP Series can also help to reduce the complexity of enclosure design and testing, for lower overall product costs. Installation via ultrasonic welding is fast and easy, and creates a secure, durable bond to the grades of plastics (typically PBT and PA) used for electronic modules.

As with all Gore weldable vents, the new High WEP Series meets the industry’s most rigorous standards for validating EEM reliability. Gore’s membranes are tested for compliance with ISO 16750 / ISO 20653 or LV124, and GORE® Automotive Vents comply with TS16949 quality standards as well as the PPAP / VDA approval process.

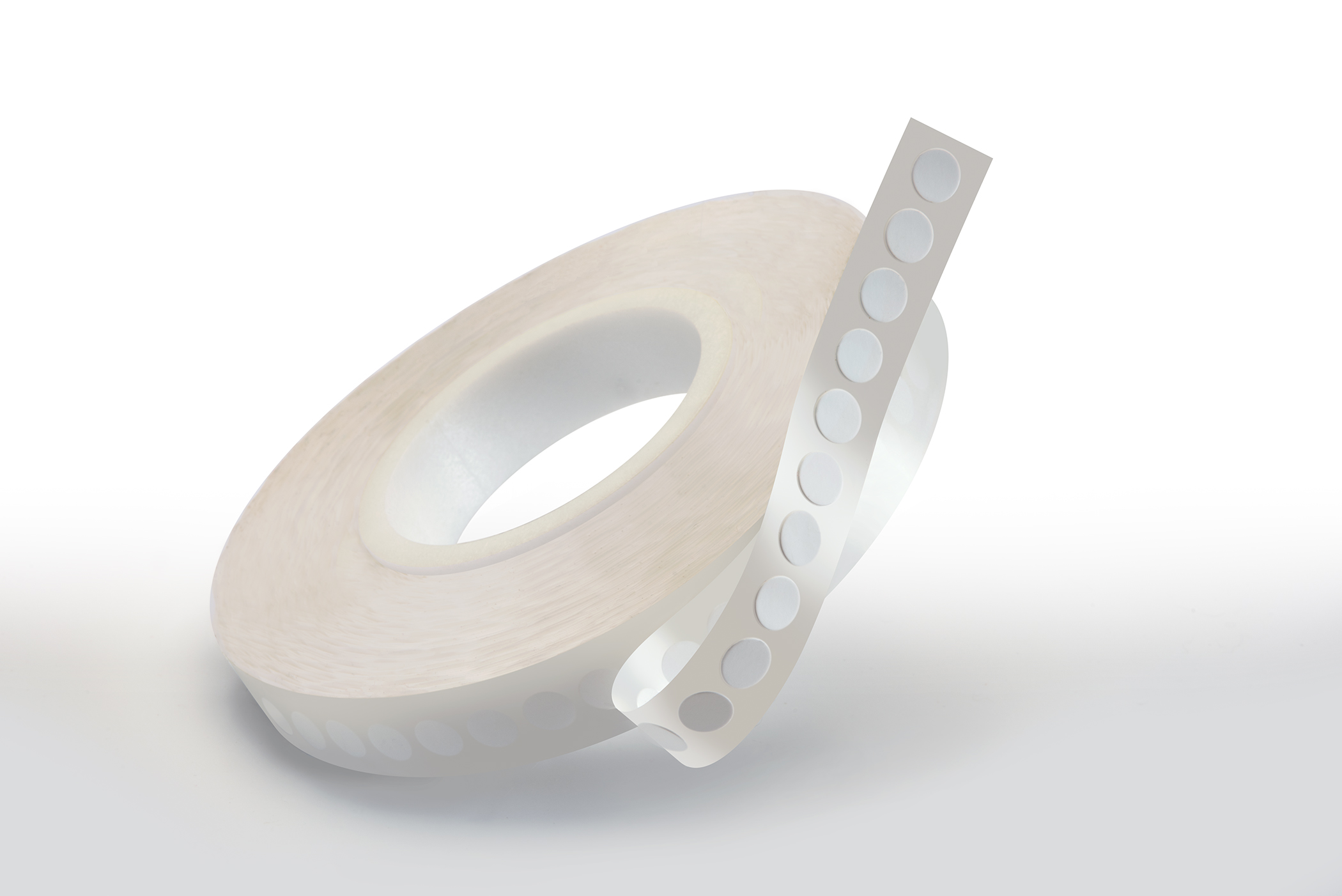

Configured as a cut-part product on rolls, Gore’s High WEP Series is available in five standard diameters from 6.00 mm to 14.00 mm.

Filed Under: M2M (machine to machine)