Manufacturers continue to seek out technologies that improve machine flexibility and accuracy. For Trumpf Laser, Schramberg, an additional goal is to speed up laser welding production processes for its customers. Trumpf is a developer and manufacturer of machines and systems equipped with solid-state lasers for automotive or medical applications. Recently, its engineers decided to integrate vision technology into the scanner optic on their laser machines. The scanner optic is known as the PFO (programmable focus optic).

Vision would make it possible to automatically adapt the welding position to match each work piece position and size without having operators orient and clamp the piece. The vision system would determine coordinate transformation data.

For the integration, Trumpf chose to work with Rohwedder AG Vision Technology, a company based in Markdorf with a staff of experienced vision specialists. The company is also one of Cognex’ Partner System Integrators (PSI).

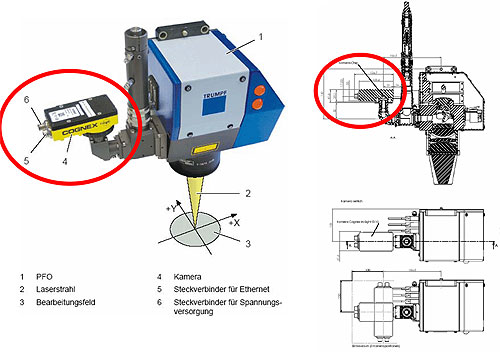

The engineers chose the In-Sight™ 5100 family vision sensors, which conform to IP67 (NMEA 6), making them suitable for demanding applications like welding. It is mounted straight onto the PFO because of its compact design.

Reliable and accurate image processing based on ‘PatMax’ enables Trumpf laser machines to precisely weld workpieces without mechanically fastening or positioning them in place.

Because of the vision sensor, Trumpf no longer needs complex clamping and positioning devices. The vision sensors can find small parts. Waste is reduced and production costs are cut.

Here is a schematic design of the programmable focusing optics (PFO) equipped with In Sight 5100 vision sensor.

Instead of grey-shade correlation, Cognex’s PatMax vision software uses the geometric structures of objects such as edges, dimensions, shapes, angles, curves and shading to localize their form. The three-dimensional relationships between these central features of the acquired image are compared to the real-time image. Data analysis allows the laser to accurately locate the object. For standard applications the response time for a complete image evaluation is roughly 180 msec.

Images and coordinate data are gathered by In-Sight and transferred through Ethernet to the laser’s FDP server. In-Sight dispenses with the need for an image processing PC. Based on the Microsoft Windows XP operator interface, the tools in this software package ease programming and integration of the vision system to the laser server’s fault diagnosis using WinLas software.

Cognex

www.cognex.com

::Design World::

Filed Under: Factory automation, Lasers, TEST & MEASUREMENT, Vision • machine vision • cameras + lenses • frame grabbers • optical filters

Tell Us What You Think!