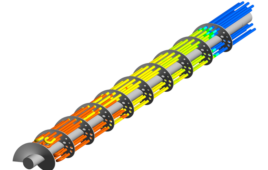

Industrial 3D printing has made a tremendous impact on the manufacturing world. Rapid prototypes are possible within a day, material selection continues to grow stronger and parts with un-manufacturable designs have found their happy place. Recently, some have started using 3D printing to produce injection molds. During this webinar, we’ll discuss the differences between 3D-printed plastic molds, machined aluminum molds, and steel production molds.

Industrial 3D printing has made a tremendous impact on the manufacturing world. Rapid prototypes are possible within a day, material selection continues to grow stronger and parts with un-manufacturable designs have found their happy place. Recently, some have started using 3D printing to produce injection molds. During this webinar, we’ll discuss the differences between 3D-printed plastic molds, machined aluminum molds, and steel production molds.

Things you’ll learn:

- Opportunities and challenges with 3D-printed molds

- Opportunities and challenges with aluminum tools

- Comparing tool quality, cost, and speed of production

- Why machined aluminum tools are geared for rapid injection molding

- Why we don’t 3D print molds at Proto Labs

Featured Speakers

Tony Holtz, Technical Specialist, Proto Labs

Tony Holtz, Technical Specialist, Proto Labs

Tony Holtz is a technical specialist at Proto Labs, a digital manufacturing company specializing in quick-turn 3D printing, CNC machining and injection molding. Holtz has been with Proto Labs for more than 15 years with roles ranging from CNC mill operator to mold designer to customer service engineer. While his formal education is in industrial machinery operations, he has extensive knowledge and experience in both traditional and advanced manufacturing processes and materials. Throughout his tenure at Proto Labs, Holtz has worked with countless designers, engineers and product developers to improve the manufacturability of their parts.

Leslie Langnau, Managing Editor – Moderator, Design World

Leslie Langnau, Managing Editor – Moderator, Design World

Leslie has more than 20 years experience as a technical editor and trade journalist. She has reported, investigated, and written extensively on the following subjects: mechanical automation, industrial networking, additive manufacturing, and automation controls. She has a B.S. degree in Mechanical Engineering from Michigan State University.

Watch the webinar anytime on demand

Sponsored by:

Filed Under: Molding • injection molding components, WEBINARS

Tell Us What You Think!