Vincor International’s Quebec is Canada’s largest producer and marketer of wine and related products. The Quebec winery is one of eight worldwide operations spread from New Zealand to the U.K. and California. The issues with the three-year-old, low frictional acetal conveyor chain were wet labels, mechanical reliability and soap costs, and increased costs. These problems drove the decision to retrofit the Quebec line with the flat conveyor, System Plast NG chain, from Power Transmission Solutions, a Business of Emerson Industrial Automation. The 200-ft bottling line runs at 70 fpm, producing about 86,000 bottles per shift, with two shifts per day. In addition to the operating cost of the line, the purchase of soap and water was about $3,400.

Vincor International’s Quebec choose to retrofit a conveyor line with a flat conveyor chain, which helped cut costs.

Another problem occurred when operators would clean the conveyor after processing high-sugar-content wines. Because sugary wine spillage sometimes acts as an adhesive if the conveyor is stopped for an extended period, the chain often broke when the conveyor re-started.

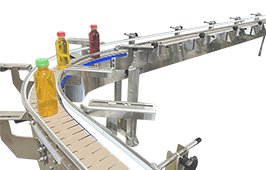

Other issues were improperly designed 90-degree turns and curves, causing unreliability in the track, and noise. Eventually, the chain wore out prematurely and would jump off track during a line re-start. This jump was due to the curves having too few magnets to hold the chain in place as it was pulled around a curve. As part of a complete changeover to dry running operation with System Plast NG chain, Merley Chain (Emerson’s master distributor in Milton, Ontario) diagnosed the problem and recommended double-magnet curves made from ultra-low-friction Nolu-S. The flat conveyor chain is made from a high-performance PBT thermoplastic, with the lowest coefficient of friction in its range. Suitable for high-speed and dry running applications, it delivers medium strength, good wear resistance, reduced plate wear and pitch elongation, lowers power consumption and noise, and increases belt fatigue factor by up to 60%. It meets the Code of Federal Regulation compliance published by the FDA’s Directive 202/72/CE of August 2002, which relates to materials in direct contact with food.

Improperly designed 90-degree turns and curves caused unreliability in the track and noise.

Nolu-S wear strips and guides are FDA approved, enable reduced-lubrication, and have high-speed conveyor operation. Made from a compound of UHMW-PE with a solid lubricant, these strips and guides dramatically reduce the coefficient of friction, maintain a UHMW characteristic, and have higher thermal conductivity. This lubricant extends chain life, does not damage or scratch PET bottles, and reduces energy consumption, noise and squeaking.

Using the conveyor chain with the wear strips, the conveyor has a coefficient of friction of 0.13 – a fraction of traditional plastic belt, steel and low-friction acetal components – thereby reducing the conveyor’s energy requirements by up to 30%.

With the wear strips, the conveyor has a coefficient of friction of just 0.13.

The term “dry wine” has a new meaning at Vincor’s bottling operation since the conveyor line eliminated soap-and-water lubrication by installing System Plast NG conveyor chain and Nolu-S wear track. “Dry wine” bottling is now synonymous with significantly greater productivity, improved sanitation, reduced maintenance cost, better reliability, and reduced noise. In fact, the production increase alone paid for the switch to conveyor chain in less than a year of operation.

Emerson Industrial Automation

www.Emerson.com

Filed Under: Conveyors

Tell Us What You Think!