How is wireless product design unlike any other kind of product design? The differences are many, starting with the very “reason for being” behind the original product idea. And those differences continue throughout all of the stages of the design process.

So it stands to reason that driving the wireless product design process requires an awareness of and attention to a host of matters that ordinary product design doesn’t demand of teams, from the idea and prototype stage through the manufacturing of a finished product. For example, there are very specific testing and certification requirements that wireless devices have to meet – and it pays to keep those in mind from the very beginning stages of your project.

Whether you’re new to wireless product design or want to make sure your teams are covering all the right bases, here are the steps of the process you’ll want to follow to ensure the timely and most cost-effective delivery of your idea from the prototype to the finished product phase.

The Idea

Wireless product design deals with questions or problems that can best—and sometimes only—be answered with wireless technology and their accompanying connected capabilities.

For example, is the functionality of the device enhanced by being wirelessly “connected” and either receiving or transmitting information via the web? Successful wireless products need to have a reason for being that goes beyond an ability to access the web simply for the sake of it.

Continue to refine your idea until you can clearly and concisely explain why the product is needed, how it would be used, where, and by whom. This is called creating “use case scenarios.”

As you work on the use case scenarios, remember that you want the product to deliver value, but simplicity in design is also key. Time and again, the marketplace shows that simple designs lead to better success. So do your best to eliminate any overly complex designs in this initial idea phase.

.jpg)

For Canary’s smart home security monitoring systems, IPS developed a testing and validation protocol that enabled speedier go-to-market for the product. Image courtesy of Intelligent Product Solutions.

An often-overlooked aspect of wireless product design: Requirements and certifications

One of the unique aspects of wireless product design is the certification process. During the design process, you’ll need to work with a variety of regulatory bodies to help create product requirements for your product, including the FCC, PTRCB and UL.

Fees associated with pre-scan testing and formal testing need to be accounted for since this will drive costs and schedule. Provisions in the product functionality will need to be incorporated to assist in lab testing and debugging as well. Units will need to be provided for each level of testing so preliminary product will need to be provided prior to starting any of the testing.

The certifications required will vary based on your product’s intended use as well as where and which country it will be used in. For example, for devices intended for pharmaceutical and medical applications, certification from the FDA is important.

For cellular radios, PTCRB and FCC certification helps ensure that they will work with a specific carrier, such as AT&T as well as testing the limits for radiated power and spurious emissions. SAR testing is required for any wearable device, to test absorption of energy into the skin.

The takeaway is that clearly articulating what will be required from a certification standpoint helps to avoid roadblocks further along in the design process. Understanding these requirements and the cost and schedule impacts after concepting and refinement is already complete, is too late (or at least very costly in terms of time and money). Having to go back and retool a particular aspect of the product because it doesn’t meet certification standards will be painful and it is really preventable if not ignored.

To facilitate the certification process, look to see if there are any pre-certified wireless modules, as those will save you cost, along with saving you time in testing and in certifications.

However, keep in mind that if you combine two, separate, pre-certified wireless modules in your product (such as Bluetooth and WIFI), you will need to get it recertified as one solution. So looking at an integrated module is a great idea.

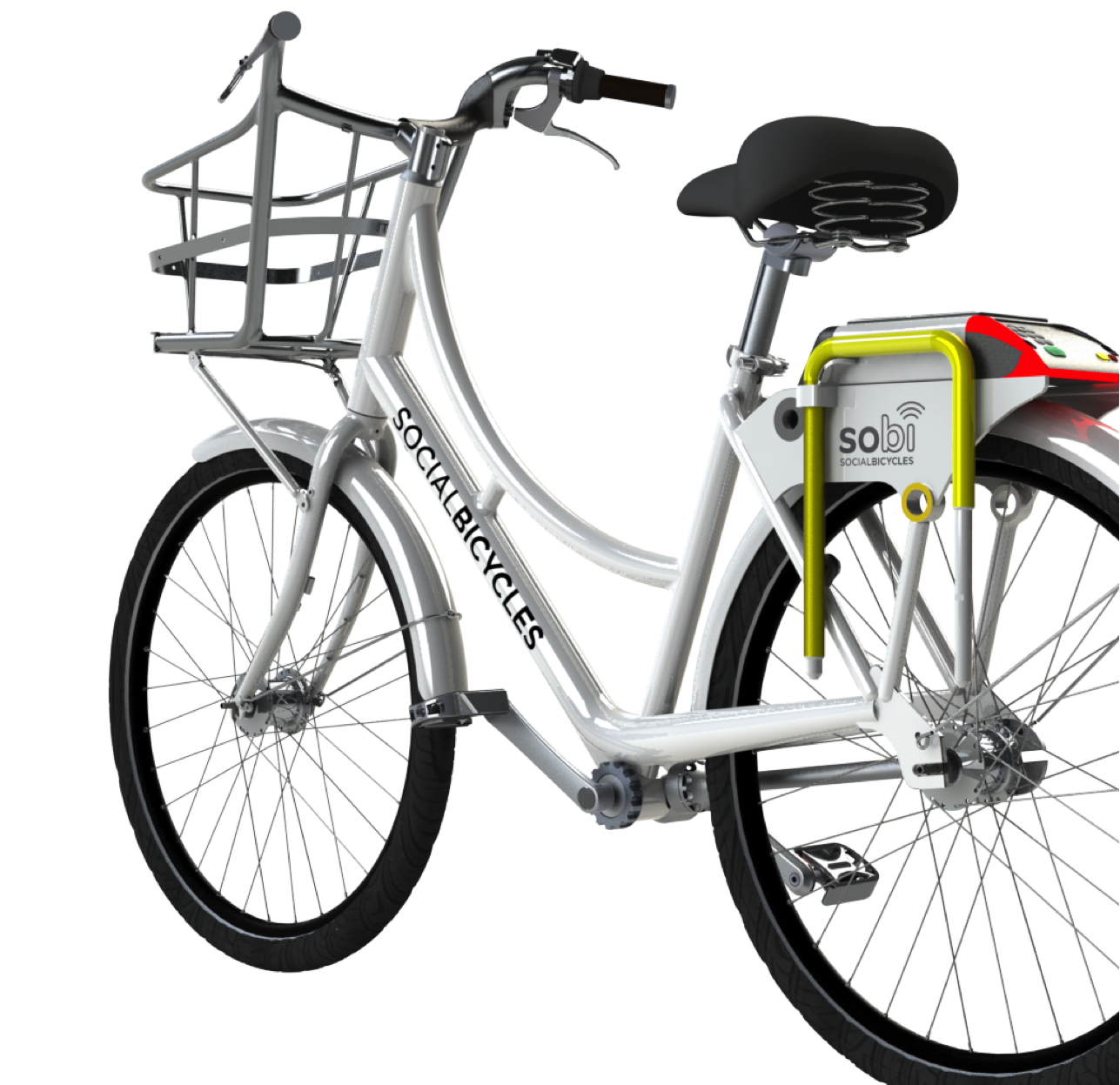

Social Bicycles that uses mobile technology and GPS to enable affordable, scalable, and intelligent bike-sharing networks. IPS played a key role in designing the RFID for these bikes. Image courtesy of Intelligent Product Solutions.

Concepting and Design

Once the product requirements are defined and initial testing complete, your teams should work closely together to refine the product design.

This phase of the process included designing the overall electro-mechanical architecture; conducting trade studies and requirement down selection; coordinating and testing the fabrication of prototypes; implementing the design drawings; and finally readying documentation for transitioning the design to a manufacturing facility.

While brief, that list comprises many, many steps (and re-steps) of nudging the product from the idea stage to the reality stage. When the first prototypes are being built, be sure to think several steps down the line to anticipate manufacturing feasibility early in the design process.

For example, how will the antennae be assembled into the product? How will other aspects of the device technology be fabricated and assembled? How will you procure the components? How can you get your procurement partner involved early?

Also, be sure to take a look at aspects of the design that can be easily overlooked in favor of more “flashy” functionality. Performance features, like how long a wireless solution can operate on a battery, can make or break a portable device in the marketplace.

Intelligent Product Solutions provided Motorola Solutions (now Zebra Technologies) with full hardware/software design and engineering support for the development of the HC1 – a wearable headset computer. Image courtesy of Intelligent Product Solutions.

Testing and Certification

When you get to the testing phase of your product prototype, work with a certification house that handles the testing to help avoid headaches and to make sure you clear all of the regulatory hurdles. But before sending your product (and paying) for testing, do some initial “pre-scanning” testing in-house.

For example, verify that you can don’t exceed the allowed transmit power just to achieve a particular range or bandwidth. Check the received sensitivity and validate whether there’s any unintentional radiation.

If the pre-scan checks out, then you can send it to the certification house with a certain level of confidence – and once testing is complete, you can attach the all-important certification label.

Make sure that your company name is identified clearly with the certification firm. Your company will need to be listed and paired to the certification label and you don’t want to always depend on an external design firm to coordinate updates to the certification if necessary down the road.

From testing to the marketplace

When the prototypes have been refined and refined again, and you’re confident that all certification requirements were satisfied, you are finally close to finalizing the product design as it would go to market.

As I’ve mentioned, I often find that the keys to success are having clear use case scenarios and product requirements (which may shift during the realization process but they need to be known by the team); the willingness to partner with a product design firm that can shepherd your team through the maze of wireless product testing and certifications; and using a certification house to clear all regulatory hurdles are key.

.png)

IPS worked with AdhereTech to design a “smart” Internet of Things pill bottle that improves medication adherence. Image courtesy of Intelligent Product Solutions.

The next step: Connecting with a product design partner

If you’re unsure of whether working with a product design partner is essential to your idea, take stock of what wireless product design experience you have in-house and what you need to procure.

Think about expertise in electrical design, firmware, antennae design, and mechanical design. Make sure that your capabilities also include a strong understanding of the different limitations of wireless technology, such as the pros and cons of cellular, WiFi, Bluetooth or others, since some wireless technologies will be a better fit for your product than others, depending on its intended use.

For instance, depending on the use cases, what wireless infrastructure can best be leveraged? If there is something existing, and does not present limitations in your offering, it may be best to leverage that, even if you don’t have the internal expertise at a particular time.

See if there are particular capabilities or skillsets you need to add to your team; while some product design firms can help you with a particular area of the product realization process, others can deliver a full range of services.

Whether you use an internal team or work with an external partner, to be successful requires strong team work. Make sure you have a team of experts in place who understand all the requirements and who can all work together.

Filed Under: M2M (machine to machine)