This webinar was presented live on Wednesday, May 8, 2019. Click below to watch it on demand.

Despite the many unique advantages of aluminum extrusion manufacturing, many product designers and development engineers still overlook it in favor of what they believe to be cheaper options. This decision is often based solely on the initial cost of an extrusion die. Most engineers don’t consider, or are simply unaware that costs and lead times for die tooling can vary dramatically based on a handful of design decisions they make.

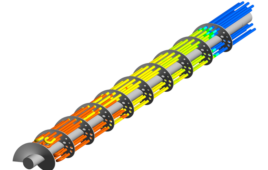

This webinar will provide a brief review of the aluminum extrusion process and then address seven factors that impact the cost of an extrusion die, including profile complexity, tolerance requirements, and alloy use. Extrusion die types and tips for driving down tooling costs will be covered.

Following this webinar, attendees will better understand:

- Costs of aluminum extrusions versus other manufacturing techniques

- Design factors that affect die tooling costs

- Design considerations to save money and time

- Why to involve an aluminum extruder early in the design process

Featured Speaker:

Carl Meyerhoefer

Extrusion Director

Vitex Extrusion

Director of Business Development

Vitex Extrusion

Senior Editor

Design World

Sponsored By:

![]()

Filed Under: WEBINARS