Traditional automation on the manufacturing floor has been machines that take input and give output. Operators give instructions to the equipment which then performs the requested procedures more efficiently than people can do. However, this automation equipment has offered little in the way of monitoring capabilities.

With the advent of the Industrial Internet of Things, or IIoT, a new era of automation technology is allowing companies to do far more with both new equipment and the equipment they already have. Now there are ways to obtain and access machine data, understand its significance, and make equipment operate more efficiently. This combination of informational and operational technologies encompasses smart automation, which enables remote equipment monitoring and management, predictive maintenance, and process optimization. Using any or all of these abilities moves you closer to the ultimate goal of smart automation: increased profitability.

Though automation and smart automation are related, they are not the same. At its core, automation uses machines and technology to improve manufacturing efficiency, increasing productivity while lowering costs. Adding a smart component is a major technological leap from traditional automation, inserting a new communication layer between operator and machine that greatly enhances the ability to further improve return on investment.

Banner Engineering is at the forefront of this automation evolution, taking a holistic approach to developing advanced technologies that give machines the ability to easily communicate with operators. This ability is achieved by taking sensor data, converting it to actionable data, and providing a vast array of critical operating information to users in real time.

Much of the smart automation technology Banner creates facilitates data collection from different types of sensors, including those from different companies; converts that data into actionable information; and shares it with anyone who needs it, even in real time. This information apprises operators of machine performance and health, giving them the tools necessary to make well-reasoned decisions about maintenance and production needs.

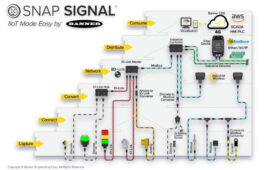

Snap Signal® and IO-Link are the two primary technologies Banner uses to deliver smart automation. IO-Link is an industry standard communication protocol that lets devices with IO-Link technology from many different companies share data with each other for seamless communication across industrial networks.

Snap Signal is Banner’s portfolio of modular hardware and software that converts signals to an industry-standard protocol from both new and legacy sensors, regardless of manufacturer. The data is distributed for easy analysis and visualization locally or via a cloud data service like Banner CDS.

With both of these solutions—Snap Signal and IO-Link—Banner can help you easily and substantially transform the way you approach automation, using data-driven decisions to enhance your productivity and profits.

Sponsored content by Banner Engineering

Filed Under: Banner Engineering Sponsored Content