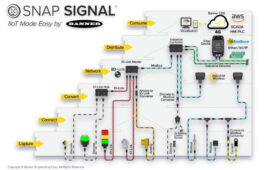

In today’s manufacturing environment, data is everything. Capturing that valuable data—information that can guide critical decisions about production, labor, and machine maintenance—can be accomplished using existing sensors and other devices without a wholesale device changeout. The ability to capture actionable machine data from across a factory is central to Banner Engineering’s Snap Signal series, a…

Boosting OEE with IO-Link

An open global standard for bi-directional serial communication among sensors and other devices, IO-Link provides simplified installation, automated parameter setting, and expanded diagnostics. Because these systems use an open standard, IO-Link enabled sensors, hubs, masters, and other devices can be integrated into almost any fieldbus or automation system. IO-Link systems have many advantages and abilities,…

Data-Driven Decision Making

Making decisions based on data, not projections or expected results, can produce far more accurate and efficient outcomes regarding your equipment. Sensor data can be collected and turned into information useful far beyond the narrow scope of part presence or absence. This information can be used to help users objectively make critical decisions such as…

At the Forefront of Smarter Automation

Traditional automation on the manufacturing floor has been machines that take input and give output. Operators give instructions to the equipment which then performs the requested procedures more efficiently than people can do. However, this automation equipment has offered little in the way of monitoring capabilities. With the advent of the Industrial Internet of Things,…