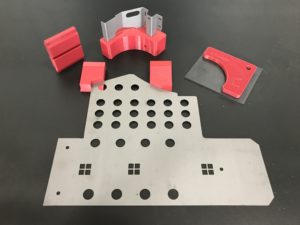

At the upcoming FABTECH 2018 show in Atlanta, GA, Cincinnati Incorporated (CI) will showcase a trio of 3D printed press brake process enhancements. The enhancements are printed upper and lower airbend tooling, printed backgage fingers and a printed inspection gauge.

3D printing of standard American style upper and lower airbend tooling is useful for specialized jobs, prototyping, or short production runs, eliminating associated engineering and production times that cause delays in getting these types of jobs up and running in a timely manner.

While many parts have complex shapes and contours, there can be challenges and delays in gaging properly and securely. With specialized 3D printed fingers, these challenges are eliminated as difficult parts are gaged in a fast, simplified, easy way.

With 3D printed inspection fixtures, all facets of a formed part can be checked at once, reducing the time spent measuring. This is useful for longer parts that require multiple check points, or for cross sections with shallow bends.

These innovations are 3D printed using PLA, which is an environmentally friendly material. Prototype fabricators working in 12-gauge or thinner materials suit the new technology, as are fabricators forming smaller specialty parts.

“We have been working with additive and press brake tooling since 2014, improving the effectiveness of forming with 3D printed pieces,” said Mark Watson, Senior Product Specialist of Vertical Motion Products at Cincinnati. “We have heard for years that you can’t find the hook that connects additive and fabrication, so we’re excited to visit Atlanta and, hopefully, start to change some minds.”

“This is very much a design tool,” Watson added. “Perhaps what we’re most excited about are all the new fabrication possibilities this can unlock for our customers. It will be a light bulb moment at the show.”

For more information visit Cincinnati Incorporated at FABTECH Booth B8439 in Metal Fabrication or B5543 in the Additive Pavilion.

Cincinnati Inc.

www.e-ci.com

Filed Under: 3D printing • additive • stereolithography

Tell Us What You Think!