EchoStorm Worldwide manufactures video and sensor management products for military, government, and commercial applications. Recently, the company was approached by the United States government to develop a product to gather aerial surveillance video. EchoStorm developed the Mobile Data Archive and Retrieval (MDAR) which combines software and hardware in a single unit. The software, called adLib, is a digital content management product that standardizes, processes, and fuses video, image, and data input simultaneously from multiple sources. The adLib software processes incoming video from unmanned aerial vehicles (UAVs) and stores it on a hard disk drive. These components are compiled into a hard enclosure and mounted in a Humvee.

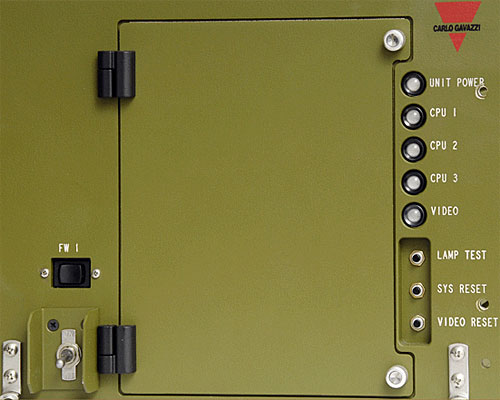

Carlo Gavazzi Computing experts developed the design and packaging of the MDAR data retrieval and archiving device for EchoStorm’s government customer.

Clark Kreston, EchoStorm’s MDAR program manager, said, “The customer wanted the software to be mounted in a particular space in an existing shelter within the vehicle and meet strict environmental criteria, such as resistance to temperature, vibration, and humidity. In addition, the customer wanted the device to provide 30 days’ worth of storage capacity. That translated to six terabytes of hard drive.”

As a result of the complexity of the project, EchoStorm contracted with Carlo Gavazzi Computing Solutions, a firm that specializes in system architecture for computing platforms, to help with the design and packaging of the MDAR unit. An electrical engineer, manufacturing engineer, software expert, and cabling person were assigned to the project. For them, one of the main directives would be to design a completely sealed box that would allow air to circulate freely through the MDAR box while not allowing outside contaminants, such as dirt and dust, to enter.

“We created a sealed box, called a re-circulating air chassis, that protects the internal electronics from the harsh environmental elements,” said Jim Tierney, vice-president of government systems for Carlo Gavazzi. “The fan design is tightly welded so no sand, dust, or salt air can enter the enclosure. Consequently, the device never requires filter changes.”

The Carlo Gavazzi team constructed its box out of a thick machined aluminum that is approximately one-half inch thick or greater in most areas. The machined surfaces are effective for thermal transfer. The heat that develops inside the box is quickly dissipated, keeping the device cool. The thermal transfer process lowers the temperature inside the box by as much as 7° C. The MDAR was designed to mount and install easily on sliders.

EchoStorm was initially contracted for 27 MDAR boxes. Today, Carlo Gavazzi is purchasing all of the internal parts based on EchoStorm’s specifications and is manufacturing and assembling the enclosures.

“All the customer has to do is turn the box on and wait a few minutes for the hardware to boot,” says Kreston. In the end, Carlo Gavazzi helped give EchoStorm the right device for an important customer.

Carlo Gavazzi

gavazzi-computing.com

EchoStorm

www.echostorm.com

Filed Under: Data acquisition + DAQ modules, TEST & MEASUREMENT, ELECTRONICS • ELECTRICAL

Tell Us What You Think!