When designing pumps and compressors, you’ll need to use couplings that balance efficient torque transfer against the ability to withstand vibration, shock loads and misalignment between the motor and drive shaft. Ringfeder offers four coupling options that help do just that.

When designing pumps and compressors, you’ll need to use couplings that balance efficient torque transfer against the ability to withstand vibration, shock loads and misalignment between the motor and drive shaft. Ringfeder offers four coupling options that help do just that.

TNR Coupling consists of an aluminum housing and steel hub, separated by cylindrical elastomer inserts that deform under shear loads as the coupling transmits torque. This solution lets you adjust torsional stiffness values to suit your pump or compressor application—a feature that also avoids resonance in your powertrain designs. In addition, the elastomers provide added flexibility to offset shaft misalignment.

Nor-Mex, a torsionally elastic, puncture-proof claw coupling solution, integrates a removable intermediate piece for the drives of pumps. This coupling is flexible in all directions, compensating for angular, parallel and axial shaft misalignments of the connected machines. The coupling transfers torque via elastomeric buffers, which form an intermediate, elastic ring. Available in various degrees of Shore hardness, this ring cushions impacts and vibrations and is electrically conductive to prevent undesirable electrical charges.

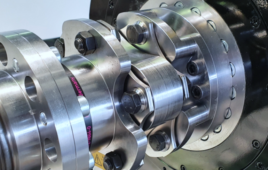

Disc Coupling offers a high level of torsional stiffness and long service life. These factors are important when you need positioning accuracy in both directions. This maintenance free solution requires no lubrication or cleaning, is able to run at high speeds due to components’ tight tolerances and is good for transmitting high torque. It also works exceptionally well under extreme temperatures—in high-temperature fluid pumps, for example.

Gear Coupling is your most torque dense solution, offering the highest torque transmission for the smallest size. Additionally, it is able to run at high speeds, conforms to the AGMA bolting pattern and is designed to compensate for angular, parallel and axial shaft misalignments within defined ranges.

Ringfeder

www.ringfeder.com

Filed Under: Couplings

Tell Us What You Think!