By Bob Kral, Bimba Manufacturing Co.

Understanding all the costs in pneumatic and electric actuators—and recognizing their very different capabilities—can save tens of thousands of dollars.

Over the past decade or two, ‘pneumatic or electric?’ seems to be the question that won’t die. Are you considering replacing a compressor and 200 pneumatic cylinders with electric actuators to save compressor costs? Thinking about building a new machine with pneumatics because 30 electric actuators cost a whopping $34,000? You might be making the wrong decision, and as a result wasting tens of thousands of dollars a year.

The choice of pneumatic or electric actuators involves an evaluation of performance, component costs, system costs and productivity gains. The two technologies are so different that one cannot be a drop-in replacement for the other. Each has inherent advantages and disadvantages.

Valves with a basic poppet design feature few sliding seals, and are pressure unbalanced.

The pneumatics side

Pneumatic actuators provide high force and speed at low unit cost in a small footprint. Force and speed are easily adjustable and are independent of each other. The typical pneumatic application employs over-sized cylinders as a safety factor. This is common because pneumatic cylinders are inexpensive and stepping up to the next larger diameter is feasible and practical. Prices for non-repairable rod-type cylinders range from $15 to $250 depending on body diameter, stroke and options.

Pneumatic cylinders provide more force and speed per unit size than any other technology except hydraulics. Pneumatics are most economical when the scale of deployment matches the capacity of the compressor. Small compressors are efficient and economical when used to power a small number of pneumatic devices. Large compressors are efficient and economical when powering a large number of pneumatic devices. Unused compressor capacity is very costly—as is time that a compressor sits idling.

While pneumatic component costs are low, maintenance and operating costs can be high, especially if a serious effort has not been made to quantify and minimize the costs. Maintenance and operating costs include replacement cylinder costs, air line installation and maintenance and electricity for the compressor. According to the Department of Energy, 24% of the annual cost of compressed air is due to maintenance, equipment and installation—while 76% is due directly to the cost of electricity for the compressor.

Determination of the operating cost per pneumatic device deployed in a facility can be eye opening, especially if cost calculations have not been done in a while and the scale of operations has shrunk. If there are 500 pneumatic devices using a compressor, cost per device may average $100 per year, but if there are only 50 devices, then cost per device balloons to $1,000.

The electrics side

In contrast to pneumatics, electric actuators provide precise control and positioning, help adapt machines to ?exible processes and have low operating cost. They are most economical when deployed in a moderate scale in processes where their performance advantages can be a bene?t and when the electronics are separate from the actuator to segment and minimize replacement costs.

Electric actuators consist of a ball, acme or roller screw connected via a coupler to an electric motor. As the screw turns, it moves a piston, which is connected to the rod or carriage. The rod or carriage moves the load. Performance varies depending on materials used. Commonly used motors include steppers and servos. Brush dc motors and ac motors are sometimes used with limit switches when positioning accuracy is less critical. Step motors are an economical choice for accurate positioning at lower speeds. However, steppers might lose synchronization with the controller when employed open loop without an encoder or if they are undersized for an application. Servos by de?nition are closed loop and provide superior performance at high speeds, albeit at a higher cost. High precision screws and anti-backlash mechanics can provide accuracies to ten-thousandths of an inch. Standard precisions with standard components range from a few hundredths to a few thousandths of an inch.

Speed and thrust are related in the physics of an electric actuator. Speed is surrendered for thrust and thrust for speed—an important distinction from pneumatic cylinders. For a given electric actuator, more thrust will be available at low speeds and less thrust at high speeds. This characteristic is more pronounced with step motors and less with servos. For this reason, accurate sizing in an application is critical. Increasing thrust at the same speed requires different designs using different components and materials. An increase in thrust and speed requires larger and more powerful components and materials, which increase costs.

Understanding and evaluating loading in the application under real conditions ensures speci?cation of the right actuator while minimizing expense. Not understanding application loading leaves the engineer vulnerable to poor performance and high costs.

Components of an electric actuator include the mechanical actuator that translates motor rotation to linear speed and thrust, the motor, an electronic driver or ampli?er to power the motor, and a controller to control motion. The total cost for these components ranges from $800 to $3,000 and up.

Operating costs of electric actuators are largely due to motor power draw. Controllers’ and drivers’ low voltage circuitry consumes power to a far lesser degree.

While component costs of electric actuators are high, operating costs are low. High component costs often deter the use of electric actuators. Savings in operating costs compared to pneumatics are not adequately considered or ignored.

For example, manual changeovers (adapting a production line to a different product) can be expensive in terms of both lost production and man-hours required to implement the change. Over the course of a year, if changeovers are required once a week and each changeover requires two people for four hours at $50/hr, man-hour costs amount to $20,800/yr. If products are produced one per minute and the value of each product is $10, lost production costs amount to $124,800. The total annual cost of changeovers amounts to $145,600. Electric actuators can substantially reduce changeover costs. The annual cost savings must be considered as part of the implementation decision.

When replacement cost, operating cost and process efficiency are considered, electric actuators’ annual costs are comparable to pneumatics’. It helps when the scale of deployment is moderate and when motion system components can be replaced separately as they wear rather than replacing an entire integrated actuator motion control system.

Example 1—The Case for electrics

Situation

A plant uses a 100-hp compressor operating at full load 2,000 hours per year at 90% ef?ciency. It powers 20 pneumatic actuators, which average $50 apiece. When the compressor is not being used, it is idling at 25% power and 85% efficiency. The pneumatic actuators average a three-year life. Cost of electricity is $0.10/kWh.

Electric actuators are being considered as replacements. The electrics average $900 apiece plus another $1,200 for controls and power supplies. Each actuator draws 6 A fully loaded at 48 Vdc 30% of the time. The remaining time the actuators draw 3 A. The power supply used draws 6A at 120 V ac under full load, producing 9A at 48 Vdc. The mechanical actuators have a three-year life span, while the electronics have a ten-year life span.

Life spans identi?ed here are assumptions. Actual life spans of components will vary.

Additionally, electrics will automate a line change that consumes two hours every week for two people at $30 an hour apiece and causes a loss of production. For every hour of production, 100 products can be produced at $1 each.

Cost of Pneumatics:

Annual cost of compressed air, compressor at full load = $21,822

Annual cost of compressed air, compressor at 25% = $19,351

Replacement costs of actuators = $333/year

Total cost for pneumatic solution per year = $41,506

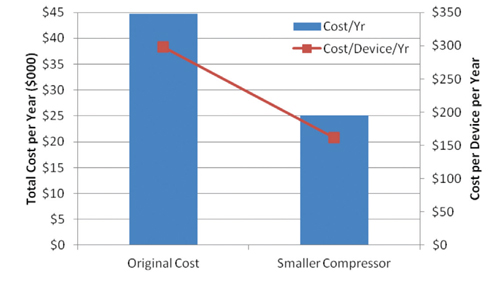

If we are able to replace the old 100-hp compressor with a smaller 50-hp unit, costs will drop as shown in the following chart. A new compressor pays for itself in about a year and a half. If the compressor is turned off when not in use, costs would decrease even more. These relationships are shown in the graph below. Savings could be as high as $25,000 per year. Note that the actual cost per pneumatic actuator deployed drops from over $2,000 to about $300 apiece due to efficiencies in deployment.

Cost of Electrics:

Annual cost at full load = $576

Annual cost at idle = $672

Annual operating costs for 20 actuators = $1,248

Replacement cost for actuators = $6,000

Replacement cost of electronics = $2,400

Total cost for electric solution per year: $9,648

Savings: elimination of change over labor = $6,240

Savings: elimination of lost production due to changeover = $10,400

Conclusions

In this instance, operating and maintenance costs clearly present the electric solution at a substantial advantage. Notice that total cost per year is $9,648, not including savings obtainable from increased adaptability of the machinery. Once we consider the gains from eliminating changeovers, implementation of the electric actuators actually reduces cost, rather than adding to it, by about $7,000/year.

Example 2—The Case for Pneumatics

Situation

A plant has a 200-hp compressor installed for pneumatics, operating at full load 2,000 hours per year at 93% efficiency. It will be used to power 150 pneumatic actuators, which average $50 apiece. When the compressor is not being used, it is turned off. An alternative is to use electric actuators. The replacement actuators cost $1,200 apiece, which includes built-in drivers and controls but not power supplies. Each actuator draws 6A fully loaded at 48 Vdc, which is about 30% of the time. The remaining time the actuators operate at 3 A. The power supply used draws 6 A at 120 Vac under full load, producing 9A at 48 Vdc.

Cost of Pneumatics:

Annual cost of compressed air = $42,237

Replacement costs of actuators = $2,500/year

Total cost for pneumatic solution per year = $44,737

Cost per pneumatic device per year = $298

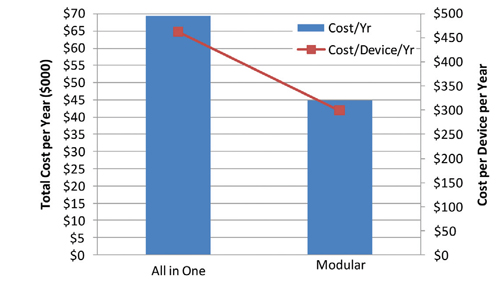

Even with a large 200-hp compressor cost per device is extremely low, bene?ting from the large scale of deployment. If a 100-hp compressor could be used instead costs can be cut further, as shown in the following chart.

Cost of Electrics:

Annual cost at full load = $4,320

Annual cost at idle = $5,040

Annual operating cost for 200 actuators = $9,360

Replacement cost for actuators = $60,000

Total cost for electric solution per year: $69,360

Because of the large scale of deployment, replacement costs of actuators increase the annual system cost, making electric actuators impractical. The solution needs a productivity improvement to make it worthwhile pursuing.

Conclusions

In this instance, pneumatics proved to be the more economical alternative. Compressor utilization is more efficient because of the higher number of pneumatic actuators deployed. Electric actuator replacement costs drive up the electric system costs. Even with a modular electric actuator design, costs are substantially above pneumatic.

Controlling costs

The initial cost of actuators is only one small consideration in a list of issues for intelligent and cost-efficient automation implementation. The high cost of electric components can be misleading, but so can high compressor operating costs. Neither tells the whole story.

Pneumatic operating costs can be controlled by sizing the compressor to ?t the scale of pneumatic device deployment. Electric actuator costs can be minimized by accurate sizing, buying motion control components separately, and selection for applications where their use improves process efficiency. Pneumatic actuators have advantages in cost, size, thrust and speed, but electrics have advantages in accuracy, ?exibility and control, making machinery and processes more efficient. An upfront estimated assessment of an application can prevent oversights and produce considerable cost savings in the long run while also ensuring that equipment matches the tasks at hand.

Bimba Manufacturing Co.

www.bimba.com

::Design World::

Filed Under: Factory automation, Actuators, Pneumatic equipment + components, FLUID POWER

Tell Us What You Think!