For one industrial pump manufacturer, a heavy-duty 0.187 in. diameter Coiled Pin attaches an aluminum shaft to a powdered metal rotor in a variable speed marine pump. The shaft/rotor is exposed to 12.5 ft/lbs of torque and the pin has worked well for years.

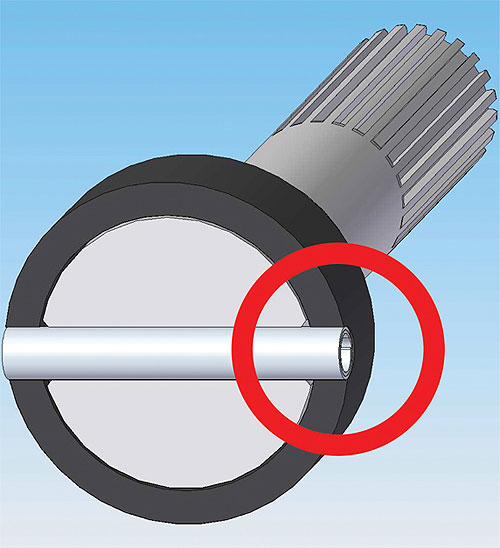

Coiled pin fastens the shaft to the rotor in a marine pump design.

For a new marine pump design, the shaft/rotor is exposed to 20 ft/lbs of torque. The pump designer wanted to ensure proper pin selection to absorb the additional torque. He wanted to use the same pin in both applications, but in trials with the new pump design the pin sheared. Spirol application engineers evaluated the new pump and found that several design elements were placing extra shear forces on the pin, which could be reduced with the following changes:

– the relationship between the Shaft OD and the rotor ID be changed to have a maximum clearance of 0.005 in., which minimizes the shear plane between the two;

– the shear plane be moved to at least one diameter length away from the end of the pin (currently 0.125 in.), which ensures that the pin interfaces securely with the hole without significant movement;

– eliminate the lead-in on the aluminum shaft which contributes to a poor shear plane at the shaft/rotor joint.

Analysis of a new pump design, though, showed the need to adjust the shear planes.

Based on the advise of Spirol application engineers, a change to the design enabled the design engineer to use a small diameter coiled pin.

The application engineers also suggested a change to the pin. In this case the pin is installed in a soft aluminum shaft. During cycling, the heavy-duty Ø.187 pin, which is a strong yet least flexible coiled pin, breaks down the edge of the hole on the aluminum shaft deteriorating the shear plane.

Heavy-duty pins are not recommended for use in soft materials. The application engineer recommended that the customer move to a more flexible coiled pin, which in this case was the standard duty pin. The increased flexibility protects the soft material by allowing the pin to absorb the dynamic forces rather than transmitting them to the host. Additionally, by correcting the shear plane issues above, the customer could move to a smaller diameter Ø.125 in. pin.

With these suggestions, the design engineer can use the same pin in both applications, reduce machining costs for the lead-in on the shaft, and reduce the cost of the pin in the assembly.

Spirol International Corp.

www.spirol.com

::Design World::

Filed Under: Pumps, FLUID POWER

Tell Us What You Think!