One way to effectively protect food from metal-particle contamination is to install an electric metal detector. Any goods affected are then rejected.

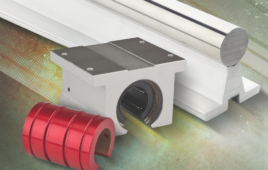

A range of self-aligning bearing materials to meet this requirement are available. An extension to the igubal® product line, this polymer material can be recognized by metal detectors. The self-adjusting bearings are manufactured from tribo-optimized polymers. They are easy to install, adjust to all angular misalignments and can replace metallic components in many applications. These bearings are up to 80% lighter than traditional metal bearings.

The detectable bearings are dry running, unaffected by dirt and dust contamination, can operate in liquids and a variety of chemicals, and are corrosion resistant. Application temperatures can range from –40° to 176° F. In addition, the components can absorb very high forces because the plastic material of the two-part combined bearings absorbs vibrations, in contrast to steel bearings.

igubal spherical bearings suit a number of industries. They eliminate the need for exact shaft placement and housing. The complete igubal® range includes lubrication and maintenance-free rod end bearings and clevis joints, flanged units, press-fit and pedestal bearings. Both the housing and spherical balls are made from detectable plastic. Standard metal-detection systems can detect all potential plastic residues, even down to the tiniest particle, and then select these for rejection.

igus

www.igus.com

Filed Under: Bearings, Packaging

Tell Us What You Think!