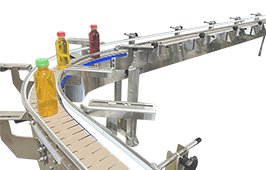

For those applications that require conveyor flexibility, but with a small footprint to save valuable floor space, Dorner’s FlexMove Helical Plain Bend Conveyors offer the solution.

FlexMove Helical Plain Bend Conveyors provide customers with unlimited configurations, including flat to flat; flat to incline or incline to flat; or incline to incline. These configurations, which also include inclines and declines through corners and straights, provide great flexibility for applications involving product buffering especially in corners. The conveyors also come with a patented side roller chain to reduce corner friction.

Features and specifications of the new FlexMove Helical Plain Bend Conveyors include:

- Available on FlexMove Conveyors: FS (65 mm); FM (85 mm); FC (105 mm); FL (150 mm); FU (180 mm); and FV (260 mm)

- Minimum 500 mm radius helical bend corner

- Corner angles: 45°, 90°, 135°, 180°, 225°, 270° and 360°

- Incline and decline angles up to 12°

- Plain chain capable of incline / decline angles up to 7°

- Friction chain recommended for angles of 7° to 12°

- Available in bearing chain and non-bearing chain models

- Load capacity for both: 300 lb

- Maximum speed for both: 180 ft per minute

For more information, visit dornerconveyors.com.

Connect with Dorner on Facebook, Twitter, YouTube and LinkedIn

You may also like:

Filed Under: Conveyors