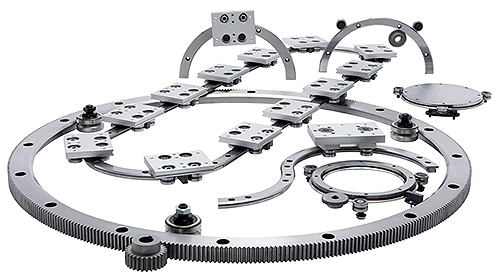

Pittsburg, CA – – Bishop-Wisecarver Corporation announces the availability of the recently revised HepcoMotion Precision Ring Track PRT2 system, an even more comprehensive range of ring slides, ring segments, bearings and ancillary components to suit the majority of rotary and track system applications that allow for imaginative and highly reliable technical solutions to be engineered.

The PRT product line, now available in stainless steel as standard, includes a wider range of sizes with lower and higher load capacities. This friction-free, debris-tolerant system also includes several new options which comprise of increased bearing and lubricator sizes, floating bearings, fixed center carriages with clamping brake, continuous bleed lubrication to reduce downtime, and the availability of pinions.

The extensive selection of ring slide types – double edged, single edged, internal/external vees, gear cut or plain – in various diameters, are available in both steel and stainless steel with hardened vee edges for maximum wear resistance. This will provide circular motion control at the edge where it is needed and a large hollow center to accommodate other components, services and even people as in the case of an MRI scanner. Track systems can also be combined with ring segments to create virtually any shape.

Five sizes of bearings are available in a variety of formats in both twin and double row configurations to suit most design requirements. The special raceway conformity and low radial clearance make these bearings specifically suited to ring slide applications. All are lubricated for life internally and are available with metal shields to prevent the ingress of liquids and debris.

Turntable applications are now possible with the addition of precision ground ring discs, providing large precision mounting surfaces that can be easily customized to accommodate a customer’s components.

Bishop-Wisecarver

www.bwc.com

::Design World::

Filed Under: Factory automation, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!