For customers looking to reduce their sanitary conveyor system’s power consumption by as much as 55%, the new iDrive2 permanent magnet motor for Dorner’s AquaPruf conveyor is a great option.

For customers looking to reduce their sanitary conveyor system’s power consumption by as much as 55%, the new iDrive2 permanent magnet motor for Dorner’s AquaPruf conveyor is a great option.

Supplied by OneMotion, a packaging automation products OEM and trusted Dorner partner, the permanent magnet motor uses less energy to run at higher speeds because its design is completely gearless. The motor’s direct-drive system uses fewer rotating parts and specially engineered magnetic arrays to cut down on energy loss through gear motion transfer.

The iDrive2 is now an option on Dorner’s AquaPruf conveyor. Not only does the iDrive2 reduce energy consumption, but its overall design also enhances the conveyor’s sanitary attributes. The motorized roller is completely oil-free, eliminating the risk of oil leaking onto the belt and contaminating product.

Performance features and benefits of the iDrive2 permanent magnet motor include:

· IP69k certified

· 43% more efficient than conventional drum motors

· 55% more efficient than traditional AC motor and gearbox systems

· Precision start and stop ability

· Solid cut shell for improved sanitation

· Multi-drive options available

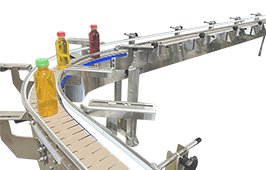

Dorner’s redesigned AquaPruf hygienically engineered stainless steel conveyor meets the latest sanitary standards and requirements of the food industry today. The updated conveyors improve upon the already fast cleaning times of the AquaPruf platform. All AquaPruf conveyors feature tool-less disassembly, with complete disassembly in less than three minutes for cleaning.

Features:

· Optional frame cut-outs and belt lifters for continuous access inside the conveyor

· Solid UHMW wear strips can be removed quickly without tools for cleaning

· Tip-up tails for quick release of belt tension

· Continuous TIG-welded 304 stainless steel frame eliminates fasteners in the food zone

· Patented sprocket alignment key

Dorner

www.dornerconveyors.com

Filed Under: Conveyors