Verallia, Saint-Gobain’s Packaging Sector, uses Abaqus and Isight to optimize bottle shape and weight early in the design phase.

by Chris Hardee, edited by Evan Yares/Senior Editor & Analyst, Software

To Dom Pérignon, the 17th century French Benedictine monk, the presence of bubbles in the wine he produced was a fault that often led to wine bottles failing from the pressure of carbonation. Yet, it was his research to prevent unintentional secondary fermentation (refermentation) in still wines that influenced the development of modern sparkling Champagne.

Today, research engineers working for Verallia at Saint-Gobain’s Research Center, near Paris, make sure that the bottles they produce are optimized to withstand the pressure generated by sparkling Champagne. Xavier Brajer, a mechanical engineer responsible for the 15-person Mechanics of Materials Group in the company’s R&D department, leads these efforts. Central to the group’s analyses are initiatives—from the government, wine and beverage industry, and Saint-Gobain itself—to reduce the quantity of raw materials used in the bottle-making process. “In order to reduce our impact on the environment, we want to minimize the materials and energy used,” said Brajer, “and at the same time guarantee that the bottles have mechanical properties that will maximize their lifetime.”

Glass bottles are made from four readily available materials: silica (sand), soda ash, limestone, and cullet (recycled glass). Coloring agents are also added, depending on the beverage being bottled and the customer’s wishes. An average empty 750 ml wine bottle weighs about 500 grams (some are as light as 300 grams), accounting for about 30% to 40% of the bottle’s weight when full. A champagne bottle weighs about twice that amount, as it must resist pressures ranging up to 90 psi (620 kPa). While champagne produces the highest gas pressure of any beverage, every carbonated drink—including hard cider, soda, and other sparkling wines—creates internal stress on the glass that needs to be considered when designing lighter bottles.

Exploring bottle shape and strength with simulation and optimization

Despite the fact that beverage containers come in an almost unending variety of shapes, sizes and colors, the profile of a champagne bottle is easily recognizable from a distance. Even the heft of the container is part of its perceived quality. Other bottle shapes are also closely associated with specific beverages or brands. So changing a bottle’s shape to reduce weight and materials treads into sensitive territory. Given that, when it comes to making these changes, Brajer and his R&D team consider the subjective aesthetic factors. But they do so while relying on objective engineering tools.

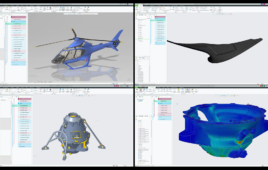

“We start with a CAD model of the bottle shape that has been drawn by Verallia’s design department, in agreement with the customer,” said Brajer. “Then as we try and reduce the weight of the bottle, we use Abaqus finite element analysis (FEA) to simulate stresses and couple that with Isight software to optimize the geometry so that the container will withstand those stresses without breaking.” Saint-Gobain has been using Abaqus, the SIMULIA brand for realistic simulation from Dassault Systèmes, for about 15 years, and started using Isight (also from SIMULIA) for automated and integrated simulation process flows about two years ago. “These two software packages link together easily and allow us to run a series of calculations that save time while leading us to the optimized bottle geometry,” Brajer added.

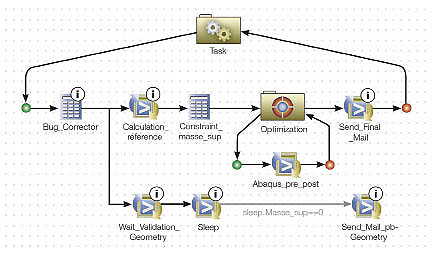

This Isight workflow, with an embedded Abaqus FEA loop, allowed the Verallia design team to systematically optimize bottle shape, making slight changes in the bottle’s geometry parameters in each iteration. The automated process shortened analysis time from one week to one hour.

In a recent optimization analysis, the Saint-Gobain research team tested a lightweight design for a hard-cider bottle. Like champagne, this carbonated alcoholic drink creates internal pressure loading that is most likely to rupture the bottle at its weakest point—the bottom. So while trying to reduce the overall amount of material, it is on this region that Brajer and his team focused their engineering analysis, looking to maintain its mechanical resistance and strength (see sidebar).

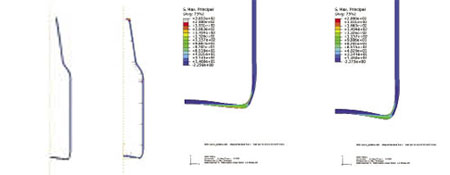

The team started the pressure analysis by first creating a model of a reference bottle in Abaqus: A 2D model using glass’ basic material characteristics was used to take advantage of the bottle’s axisymmetric geometry and save computing time (see Figure 1). They then meshed the model and applied boundary conditions and loads. To optimize the geometric parameters (in this case nine, but sometimes more) that were used to describe the bottle’s bottom—such as internal and external shape, curvature, and a number of different radii—Abaqus was coupled with Isight. This allowed the team to automate the simulation workflow and systematically make changes in the parameters, calculate stresses for each profile, and ultimately determine minimal stress and optimal bottle shape (see Figure 2). “In the case of the hard-cider bottle, we were able to reduce weight by 10% and stress on the critical bottom region by about 17%,” said Brajer. “In the past, it might have taken us a week to run the 100 simulations needed for this optimization. But now with an iterative looped process, it only takes about an hour.”

With the help of Verallia’s technical teams, physical testing was also used to complement simulation. “How we use testing may change in the future,” he said, “because once we have calculations that validate the tests, design engineers will trust the virtual optimization process.”

Simulation helps reduce bottle weight

Internal pressure loading is one of the most common causes of breakage for carbonated beverage containers. But it is not the only one. As bottles move from the glass-making mold to the bottling assembly line and then finally to the store shelf, they are filled, capped, stacked and transported. This subjects them to a variety of loading scenarios including thermal stress (from hot liquids), impact, squeezing and compression. Basically, the life of a glass bottle can be a precarious one.

Brajer and his team are working to change that. So while the pressure analysis was the first optimization study that the engineering team conducted, they intend to use a similar process—and the same software tools—to investigate the other ways that bottles break. In future designs, using fewer raw materials will remain of primary importance to the team. That’s one of the goals of Verallia R&D.

This design strategy is critically important today given the need to reduce CO2 emissions from manufacturing processes. “Our goal is to use less energy to produce each bottle,” Brajer said. “If we reduce raw materials, we reduce the energy needed to process those materials and to melt and form the glass. The amount of CO2 created in the process, in turn, is directly linked to the energy and raw materials usage.”

Given the quantities of bottled beverages and food consumed worldwide, the carbon footprint for bottle-making is worth addressing. Verallia is the second largest glass bottle and jar manufacturer in the world—with a yearly production of roughly 25 billion containers—so their strategy to optimize weight will provide significant environmental benefits.

Making and breaking glass bottles

The primary method for making narrow-necked bottles—for champagne, hard cider, or wine—is a blow-and-blow process (as opposed to a press-and-blow method primarily used for wide-mouthed jars). Employing this technique, molten glass at 1500º C, straight from the furnace, is first cooled to 1100º C in a forming machine and then cut into “gobs” (small bottle-sized amounts). Compressed air is used to blow a cavity into the hot semi-liquid material creating an intermediate shape in the forming machine. A second jet of air gives its final shape to the bottle in the blow mold. An annealing process is utilized to give the glass additional strength.

Unfortunately, glass is impossible to manufacture without tiny defects, even though the glass-making process has had more than 5000 years for technical advancement. These defects—such as small scratches or cracks in the surface—result from contact with objects and a variety of other factors and can cause a weakness in the material. “If you had a bottle without any defects,” said Xavier Brajer, lead mechanical and materials engineer at Saint-Gobain Recherche, “glass bottles would be 100 times stronger than they are.”

Bottles on the assembly line following the final step in the process.

Defects in the glass cause bottles to break according to statistically regular patterns. “If you take 20 bottles and apply a consistent pressure, some will break at 10 Bars, some at 20, and some at 30,” says Brajer. “It is regular and can be calculated because the defects obey statistics.”

Because the behavior of defects can be predicted by probability, Brajer and his engineering team use Abaqus FEA and Isight to help calculate stresses against rates of failure, while also striving to minimize the amounts of raw materials used in the company’s eco-designed line of containers. “Our goal is to find the lightest bottle that will withstand a statistically accepted maximum level of stress,” said Brajer.

Chris Hardee is a technical writer based in New Hampshire.

Dassault Systèmes SIMULIA

www.simulia.com

Filed Under: Software • 3D CAD

Tell Us What You Think!