by Natasha Townsend, Electronics Editor

The need for consistency is an industry-wide challenge. OEMs and end-customers evaluate the cost-performance advantages of emerging motion control solutions versus traditional hydraulic, mechanical and electro-mechanical machine system designs. Sunnen, an OEM, customizes high-end, bore sizing and finishing systems designs. When identifying a new market segment opportunity, the immediate problem was system cost versus market willingness to pay. But, the larger and longer-term problem was how to evolve the company’s technology platform while maintaining its competitive advantages in systems design, manufacturing and service efficiency.

Sunnen learned that Siemens could offer a basic performance servomotor, with resolver feedback, for the price of an ac motor. But, the machine designers still faced the challenge of developing an all-new system design for low-cost, while being consistent with the company’s established product platform. Siemens supported the multi-axis, high-performance, Sinamics S110 drive and automation platform.

With the basic servo-positioning package from Siemens, Sunnen’s HTA tube-hone bore sizing and finishing system has impressive performance capabilities for tube machining.

Sunnen’s engineering team first looked into developing a new basic bore sizing and finishing system to fill a gap in the product line. The engineers put together a prototype system, where the spindle response time delayed in signals between the display, PLC, and a servo and general-purpose drive. For Sunnen’s specific application, the time delay of 300 milliseconds was unacceptable. Sunnen contacted Siemens for motion control ideas.

Siemens designed a motor that fit Sunnen’s SV vertical honing line application requirements and assisted in initial synchronization and tuning. Establishing a common dc bus drive structure, the Siemens drive platform made it possible to have all the same drives in the system, for servo or vector applications. The clean and proficient design was a result of no mixes and matches of drive types.

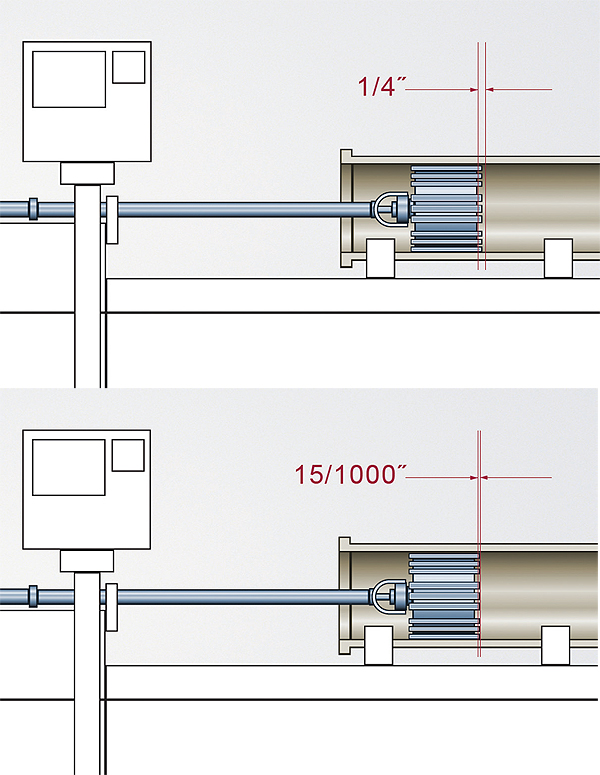

These illustrations show the ¼ in. repeatability to 0.015in. repeatability (before and after). The new HTA machine’s repeatable reversing accuracy was greatly increased using Siemens new Sinamics S110 servo drive.

The key components of the new system are an easily programmable, soft PLC at a low-cost point and low-cost distributed motion control. The Drive-Cliq cable between the Sinamics S110 drive and 1FK7 servomotor provided automatic configuration, as well as the feedback of the servo system. Additionally, the MP177 with WinAC software made the configuration and communication simple and straightforward.

The Drive-Cliq connection between motor and drive allow automatic configuration at power-up of motor and encoder parameters providing a Plug-and-Play servo system.

Both companys’ product platforms helped drive Sunnen’s business forward, enabling the company to grow in a downward economy. The company expanded its platform of high production, high precision bore sizing and finishing systems to include maintenance and repair operations honing machines. The OEM’s success is attributed to its ability to adopt simpler, yet more advanced and cost-effective motion control.

Siemens

www.usa.siemens.com/sinamics-s110

Filed Under: Motion control • motor controls

Tell Us What You Think!