by Chris Francis

Electric motors are everywhere. For example, whereas in the past a car would have had only one electric motor – for starting – (and if you go back far enough, not even that), now they have dozens of them. They control windows, mirrors, ventilation flaps and engine functions. Even power steering is often electric now. Motors are in cameras, printers, domestic appliances and also driving fans in devices which you probably don’t think had a motor. Choosing a motor driver involves firstly deciding on the type of motor. This will depend on what the motor is required to do: control position or speed, small or large. Power, torque and speed will be used to narrow the choice. The available power source will also be important – mains electricity or battery power for example. It helps to understand a few of the main motor types when choosing. Here are the most common DC motors:

Stepper motors

These move in a distinct series of steps by sequentially exciting a winding or sets of windings. A typical application might be in a printer or optical scanner. They can make a characteristic whirring noise, particularly in scanners. They usually have 20 to 200 steps per revolution. Their main use is for positioning rather than speed control, although you can also precisely control the speed. You can full-step or half-step the motors depending on the number of windings. They can also be “micro-stepped” by varying the current through windings so they motor will rest between what would normally be two steps. The current is usually varied by pulse width modulation (PWM) of the drive voltage to the windings. Some drivers have variable micro-step sizes with up to 256 micro-steps per step whereas others might be fixed at 16 micro-steps per step. The LV8713T from On Semiconductor for example can control up to 32 micro-steps. The mode is set by the MD1 and MD2 pins.

A more sophisticated device is the AMIS-30621 from On Semiconductor. This is not only a micro-stepping drive but also a position controller. You can program, acceleration, deceleration and speed and also program position limits. This removes quite a bit of functionality from the controlling microprocessor which would simply need to issue commands to the AMIS-30621, greatly simplifying the software.

Permanent magnet DC motor

A common, basic type of DC motor which is now being replaced by brushless motors in many applications. They can be used for simple movement or precise speed and position control where there is some feedback mechanism. They have brushes which wear and can cause contamination in use. Sparks and interference can also be an issue in some applications. They are simple and cheap to drive though, so are still quite common in some applications. Varying the voltage or current will vary the speed and torque under load. PWM can be used to control them for higher power efficiency than a linear control of voltage or current.

You don’t need a very sophisticated driver for a brushed motor. A simple switch or one or more MOSFETs connected to a microcontroller may be all you need, but if you use an IC of some sort you will often also have a few extra features such as a current limit and over-temperature protection.

Brushless DC motor

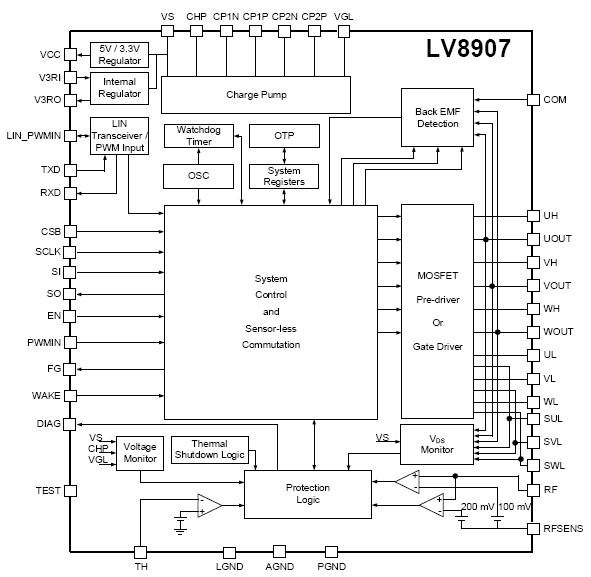

By removing the brushes and split commutator, a brushless motor requires a driver which will create the moving magnetic field required to make the motor rotate. Synchronizing the drive with the motor position can be effected either with hall sensors on the motor or by sensing the back EMF from the motor windings. The advantage over a permanent magnet DC motor is that there are no brushes to wear, no sparks and potentially less interference. Hall effect position sensors add cost to the motor so sensorless drivers are quite common for low cost applications. A smoother, quieter drive would use sinusoidal drive to the windings rather than simple on-off control. Power drive may be built in to the motor control IC or it could use external MOSFETs for higher drive current. Some newer drive chips look interesting such as the LV8907UW from On Semiconductor.

The information is only preliminary but it is targeted at automotive applications and has a LIN (Local Interconnect Network) interface. It drives sensorless brushless motors and can operate in a stand alone mode (without the LIN interface used) and has PI (proportional/integral) speed control.

Filed Under: Automotive, Microprocessors, Motion control • motor controls, ELECTRONICS • ELECTRICAL, Motors • dc, Motors • stepper

Tell Us What You Think!