Acushot, a veterinary design company, recently developed an automated, needle-free injection gun for mass livestock vaccination. The injection gun required a linear bearing system that could absorb recoil. The final design reduced moving components and weight. It is a compact and battery powered needle-less injection unit with up to 28,000 psi delivery pressures.

The elimination of needles removes the possibility of an unsafe employee needle-slip. The unit also enhances sanitary conditions; it can be used hundreds of times without risk of cross contamination to the animals.

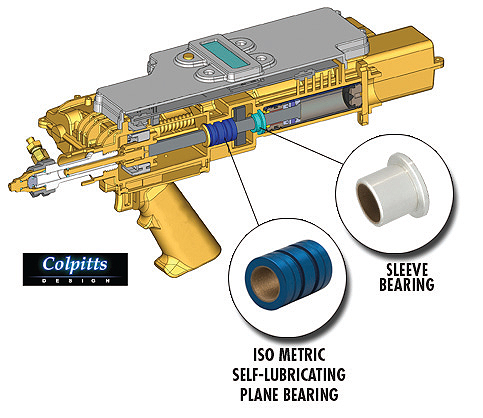

For a quick prototype and possible added refinements to their design, Acushot™ turned to Colpitt Designs—a third party engineering firm. Colpitt reduced components by using a gas cylinder with up to 600 lb of force. The cylinder injects the vaccines to the same recommended depth as that of a typical needle. The injector can be set to inject from 0.2 cc and deposit it just in the skin of the animal or up to 2.5 cc can be injected to the recommended depth into the muscle of the animal. The system also automatically time stamps each dose for accurate vaccination records.

A linear bearing assembly that could support the force of the injection delivery was critical. Throughout a cycle, 650 lb of force act on the bearings; which would be under constant use in extreme temperatures and outdoor working conditions. Colpitts Designs used Simplicity® plane bearings to withstand the system parameters and environment of the application.

Simplicity® bearings glide using a proprietary Teflon liner for even disbursement of forces throughout the bearing and smooth, reliable travel. Bronze and linear ball bushings spall the shafting under the high forces and short stroke, which accumulate and contaminate the system and can result in catastrophic failure. Simplicity bearings self-lubricate to ensure smooth and quiet operation during constant or intermittent use. They operate in temperature extremes from -400° F to 400° F.

No needle trauma recovery was necessary for the animals; in fact the livestock does not even take notice when given their injection with Acushot’s™ new injector. The unit also reduced the diameter of the injection mark to about 1/8th the size. Easy to use with no extra vaccine containers the Acushot™ system improved productivity, safety and the overall health in stockyards and barnyards worldwide.

PBC Linear

RST.pbclinear.com

::Design World::

Filed Under: Bearings, Medical-device manufacture, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!