The 2011 Graphical System Design Achievement Awards received 130 submissions from authors in 20 countries. A judging committee of NI technical experts reviewed the papers and selected the contest finalists and winners. Here’s a look at a few of them.

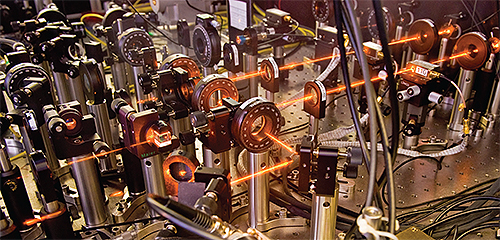

2011 Customer Application of the Year: Implementing FPGA-Based Feedback Control of a Single Atom With LabVIEW and NI FlexRIO. The researchers wanted to develop a custom time digitizer to study fundamental quantum properties of light-matter interaction. Christian Sames and his team at the Max-Planck Institute of Quantum Optics used the NI FlexRIO and the NI LabVIEW FPGA Module to build a powerful and versatile custom instrument that let them implement real-time execution of time-critical tasks in hardware. This makes it possible to implement feedback control for systems as small as a single atom interacting with single photons.

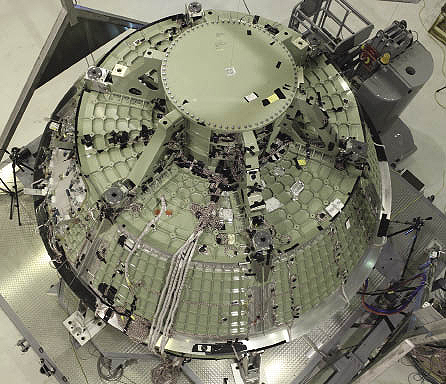

Validation test: Using LabVIEW, PXI, and CompactRIO to Rapidly Develop Structural Test Systems for a Space Exploration Vehicle, Dave Baker, G Systems

Dave Baker and the engineers at G Systems needed to design three test systems within six months to perform structural tests on the Orion Crew Exploration Vehicle. They used concurrent development and off-the-shelf NI hardware and software tools, such as NI LabVIEW and an array of PXI, SCXI, and CompactRIO hardware, to rapidly deliver all three systems.

Automated Test: Texas Instruments Increases Firmware Test Platform Throughput, Coverage, and Reliability with NI Hardware and Software

The test platform needed to be modular, abstract, scalable, and easy to use. It had to support test sequencing across hundreds of power management ICs (PMIC), and interact with multiple instruments, evaluation modules, and source measure units (SMUs). Sambit Panigrahi and the TI team used NI LabVIEW software and NI TestStand to build a flexible and modular automated test solution that can test several PMICs with different requirements, communications buses, and protocols; and is easy to use for engineers who do not have computer science backgrounds.

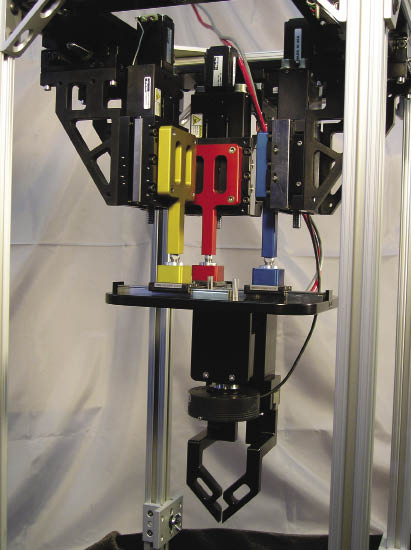

Robotics: LabVIEW NI SoftMotion Module and SolidWorks Improve the Design Process

The goal was to develop a platform to test the equations and NI LabVIEW VIs without a fabricated physical test platform after solving inverse kinematic motion equations for the six-axis manipulators, and simulating and optimizing the travel of the design as a result of motion performance tests. To accomplish this goal, Lisa Mosier and her team at Square One Systems Design Inc., created a 3D model in SolidWorks to construct a virtual, physical representation of the six degree-of-freedom (DOF) system. They used the LabVIEW NI SoftMotion Module to design VIs that could run the fabricated system and simulate its capabilities in the CAD model, and develop a fabricated system using an NI cRIO-9024 embedded real-time controller and six NI 9512 modules.

Advanced Control Systems: Positioning Actuators for the European Extremely Large Telescope Primary Mirror With LabVIEW and PXI Hardware

Miguel Núñez and his team at the Instituto de Astrofísica de Canarias were tasked with developing the electronics and embedded software needed to manage and coordinate three nanometric position actuator prototypes for the European Extremely Large Telescope (E-ELT) primary mirror. The prototypes had to move 90 Kg with nanometric accuracy while being conceptually representative of future electronics design for serial production. Núñez used the NI LabVIEW Real-Time and LabVIEW FPGA modules on the NI PXI platform to interface with several devices and guarantee low latency and jitter for a 1 kHz external command rate and even higher internal position sampling and servo control loop.

Student design showcase: Using LabVIEW to Develop a 3D Display System

Yang Hao, and fellow students at the Tsinghua University , developed an interactive 360° stereoscopic 3D film system that displays both visual models and real objects, does not require glasses, and is affordable. They developed a 3D display system that consists of three parts: acquisition, processing, and 3D display.

::Design World::

Filed Under: Factory automation, Machine tools + subtractive manufacturing, ENGINEERING SOFTWARE, Materials • advanced, Material handling • converting, Lasers, Motion control • motor controls, Mechatronics

Tell Us What You Think!