Milford, Ohio, — Parker’s Electromechanical Automaton Division, a leading supplier of integrated motion control solutions, announces the release of InteractX version 2.2 of its award-winning, OEM-friendly Windows®-based HMI software.

InteractX 2.2 offers several product enhancements, including:

• Upload functionality added to the Input List Tool. This new feature allows input list items to be uploaded from a PLC to InteractX software, complementing the existing download feature. Machine builders will particularly find this useful in customizing machine applications without special VBA programming.

• COMM Server update complete with seven new communication drivers and update/enhancements to a number of existing drivers. InteractX Deployment Server now tracks/displays all installed “Hot Fixes.”

• In developing applications, copied objects are no longer offset when pasted into another panel. This feature will help designers maintain consistent screen layouts over multiple HMI panels. Restored Interact Import Utility, which will make it easier to transition Interact customers to InteractX.

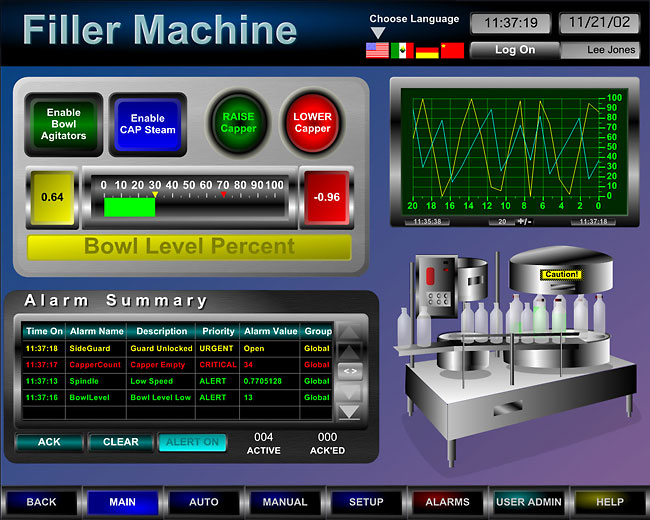

This latest version of InteractX, which is a free upgrade to users of InteractX versions 2.0 and 2.1, also offers the industry’s most streamlined HMI toolset for compliance with the FDA’s 21 CFR Part 11 and Good Manufacturing Process (cGMP) standards that require operator tracking and E-signatures. Known for its advanced graphics, ease of application and reduced cost of ownership, InteractX also includes easy electronic signatures, enhanced user administration, operator authentication, tracking and data logging audit trail functions – all without special scripting or software add-ons.

InteractX’s Operator Tracking and E-Signature tools track events transparently, as part of daily operator activities, or can be used for operator authentication and supervisor approval E-Sig compliance needs. Simple check boxes allow application developers to set approval requirements for specific events while allowing operators to indicate desired changes in machine operation, reasons and authentication of his or her identity through simple predefined popup dialogs. Multiple user levels are available to establish approval requirements, and the system logs historical data to record events, requests, identities and approvals, creating a complete audit trail on a machine or group of machines. All of this functionality is built into the standard software package, with no special programming or scripting required.

“Machine HMI presents the best opportunity to address Part 11 and cGMP requirements,” says Andy Balderson, product manager. “And now InteractX offers the industry’s easiest solution for compliance with the increasing need for operator tracking and E-Sig system requirements.”

Machine OEMs will also find it easy to deploy this solution to users in the field, thanks to auto detection of user admin security for Windows networks and seamless IT integration of MS Access, SQL and OBDC database logging. “Machine builders will appreciate the ease with which they can offer machine event tracking with InteractX and their customers will appreciate how easy it is to manage and document E-Sigs as part of their machine installation,” says Balderson.

InteractX also features fully rendered and scalable graphics, intuitive, object-style development tools, unlimited tag runtimes, 45+ standard communications drivers, real-time data acquisition, complete tag editing, integrated VBA and ActiveX tools for easy customization and built-in multi-language support. According to Balderson, “InteractX provides customers with the full functionality needed to create an HMI application – one software package scalable to a whole range of runtime systems.”

InteractX runs on Windows/2000/XP operating systems and is installed/licensed on Parker-CTC’s new HPX and PX PowerStations. These workstations can run InteractX, and other fully functioning Windows applications, on their standard CompactFlash drives, potentially making a hard drive unnecessary. HPX and PX PowerStations offer a bundled HMI solution for users who want higher Windows functionality along with a choice of 10”, 12”, 15” or 17” high-resolution touchscreen displays. Unique among Windows HMI developers, CTC offers InteractX bundled into hardware/software solutions, specifically engineered for industrial applications. “This bundling lets OEMs avoid the integration issues with hardware and software products from different companies, the typical practice until now with Windows HMI,” says Balderson.

About Parker Electromechanical Automation

A division of Parker Hannifin Corporation’s Automation Group since 1987, Electromechanical Automation is a pioneer, developer and manufacturer of full-spectrum computer-based motion controllers, servo/step motor drives, servo motors and human-machine interfaces, positioning systems, gearheads and gear motors. These products automate the manufacturing of a significant fraction of the world’s goods and services.

Electromechanical Automation products are sold via independent authorized Automation Technology Centers—a group of nearly 100 professional, highly trained organizations with more than 135 points-of-presence throughout the world—or directly from Electromechanical Automation by logging on to buy.compumotor.com. An informative and up-to-date Web site with downloadable libraries, tutorials, and background information on motion control and automation is located at www.parkermotion.com.

:: Design World ::

Filed Under: Factory automation, ENGINEERING SOFTWARE, Packaging, Motion control • motor controls

Tell Us What You Think!