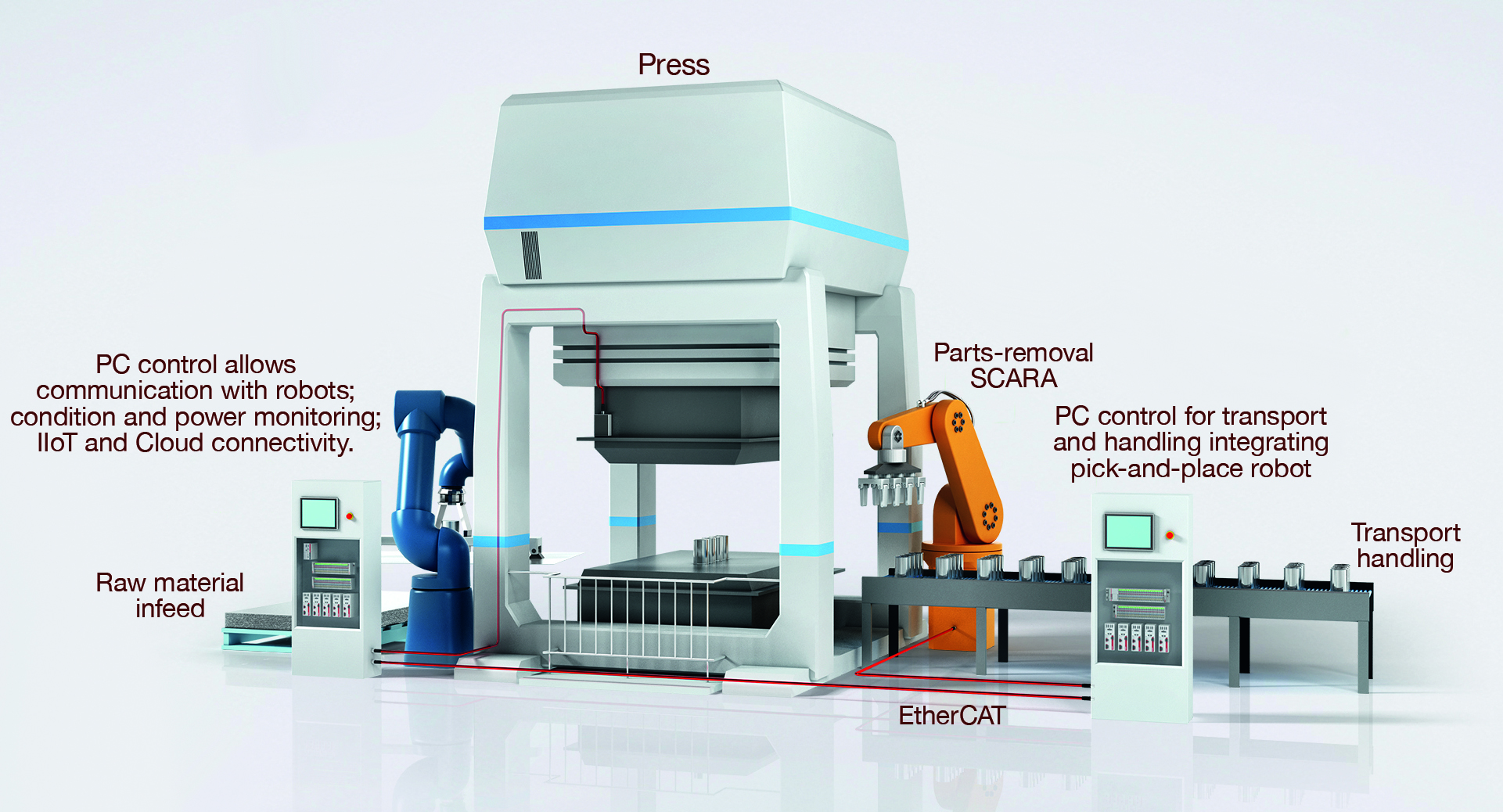

Sheet-metal workcells can deliver higher-quality parts in greater quantities than traditional builds when designed with centralized PC-based control and EtherCAT connectivity. That’s especially true of deep-drawing press applications (shown below) where modular hardware and software from Beckhoff maximize throughput and minimize tolerances.

To review, deep drawing is the process by which sheet metal is placed between two halves of a forming die and mechanically pressed via punch into a shape. Such drawing is deep drawing where the new shape’s depth is more than its diameter.

Sheet-metal workcells (such as the deep-drawing presses shown here) get higher throughput with centralized PC-based control and EtherCAT connectivity. Modular hardware and software from Beckhoff also help minimize tolerances. Press-specific software tools include a Beckhoff TwinCAT PLC Hydraulic Positioning library for implementing efficient servo hydraulics. TwinCAT Analytics leverages comprehensive data acquisition to support condition monitoring for minimal machine downtime.

Press-specific software tools include a Beckhoff TwinCAT PLC Hydraulic Positioning library for implementing efficient servo hydraulics. In addition, TwinCAT Analytics leverages comprehensive data acquisition to support condition monitoring for minimal machine downtime. The software supports OPC UA, MQTT, and AMQP standards for IIoT scalability and secure Cloud communication. Avoidance of data incompatibility and latencies (as those in communications between different systems) allows synchronization of press axes and processes — and trims the costs associated with extraneous hardware and engineering.

On the hardware side, Beckhoff Compact C6015 and C6017 Industrial PCs serve as universal control and visualization platforms or (in some setups) as IoT edge devices. (Precision synchronization makes for better workpiece quality with fewer reject parts.) Within the press itself, actuation with servo-electric hybrid axes leverages the fast motion cycles and simple mounting requirements of hydraulics while improving on their baseline efficiencies and need for maintenance. Beckhoff’s dynamic servo-drive solution consists of the AX5000 servo drive and AM8000 servomotor with One Cable Technology — controlled via the aforementioned TwinCAT PLC Hydraulic Positioning software.

For material handling into the press and machine tending, AMP8000 distributed servo drives integrate amplifier electronics directly into servomotors, allowing engineers to build modular workcells. Putting power electronics in the machine makes control cabinets smaller — to a single coupling module for supplying the workcell’s servo drives with one cable via a distribution module.

Filed Under: PCs, Motion Control Tips

Tell Us What You Think!