If you’re an engineer, you’re likely to be a lot more interested in CAD, CAM, and CAE software than in PLM software. That’s understandable. CAD, CAM, and CAE are used to create things. Creating things is fun: It’s the reason why most of us got into engineering in the first place.

PLM software, however, is not used for creating things. It’s used for managing processes—and that’s not something most people associate with the word “fun.” Existing PLM software tools are no fun to deploy, and no fun to use. They’re probably best described as “frustrating.”

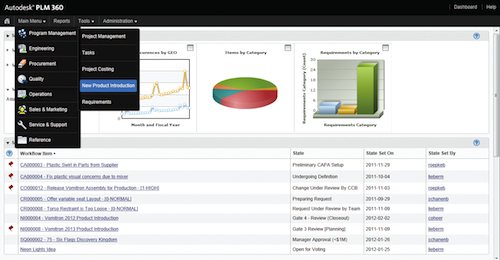

Autodesk PLM 360 provides simple access to workspace dashboards used for managing processes.

Recently, a few software vendors have started to look at the world of PLM software, to see if they can create some tools that are not quite so frustrating. While these tools may not reach the level of being fun to use, they may be able to reduce the time you spend on “not fun” tasks, so you have more time for fun things, such as engineering.

The Autodesk approach to PLM

Autodesk is possibly the largest CAD and engineering software vendor in the world (depending on how you count.) Up until recently, they’ve not been big fans of PLM —at least, as it’s done by their competitors.

In 2007, Autodesk CEO Carl Bass said “There are only three customers in the world who have ever had a PLM problem. One is Dassault, one is PTC, and one is UGS. All competitors. There is no company that I know that wakes up and says ‘I have a PLM problem.’ PLM is an artifact—it’s a marketing slogan—to satisfy a financial community… What I see in PLM is the exact opposite of what we’re trying to do.”

Recently, Autodesk showed the world its vision of how to do PLM right, with a new product called Autodesk PLM 360.

Autodesk PLM 360 is offered as software-as-a-service (SaaS), at $75 per user per month with an annual subscription, with the first three users free. It runs on the web, is accessible on smart phones, tablets, or PCs, requires no installation, and can be up and running in minutes.

PLM 360 is, at its core, a product-oriented business process automation system. It doesn’t include PDM (vaulting), but can be used with Autodesk Vault, or integrated with other PDM systems (depending on their openness.)

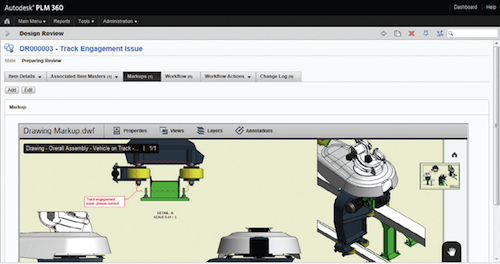

Autodesk PLM 360 design review, using DWF format markup

PLM 360 includes dozens of pre-installed apps, to support a number of business processes in the areas of program and product management, engineering, supplier management, quality and compliance management, operations, service and support, sales and marketing, AEC, PDM integration, and enterprise system integration.

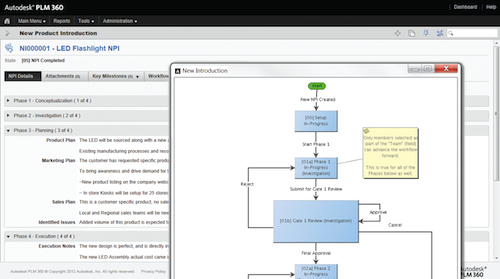

The PLM 360 apps are completely user customizable, with little specialized knowledge required on the part of the user. Workflow customization, for example, is done through a simple drag-and-drop graphical diagram editor. PLM 360 uses Javascript for process scripts, and these too are user editable—though the knowledge bar is higher for this. (Autodesk believes that most users will be able to tune PLM 360 to their needs without needing to do any Javascript customization.)

Two things that make Autodesk PLM 360 particularly attractive are simplicity of deployment and cost. It’s possible for a company to get started very quickly, by implementing just a few of the processes that are their biggest constraints, and that will provide the biggest payback. There’s no need to jump into full-blown implementation. Just use the pre-installed apps as templates, to build processes that meet your needs. Upfront costs, both in capital and time are minimal.

The implementation process for Autodesk PLM 360 is a big change from the traditional process used by other large PLM vendors. In that process, the customer needs to pay up-front for software licenses, buy and install their own server hardware, and hire consultants to manage the deployment. For medium sized businesses, the upfront costs can be several million dollars, with annual maintenance fees of several hundred thousand dollars. With Autodesk PLM 360, first year costs, including services and subscription fees, will be a small fraction of that.

No matter how easy it may be to deploy, PLM 360 is not functional match to the big three PLM systems: Teamcenter, Enovia, and Windchill. It just doesn’t do as much as these systems do. PLM 360 is unlikely to displace these systems in entrenched accounts, and particularly in large aerospace and automotive companies, where tight integration with engineering tools is critical. Yet, it’s entirely possible that PLM 360 will find its way into some large accounts through the back door—as a task specific tool for particular programs.

Autodesk PLM 360 supports drag-and-drop visual workflow editing.

PLM 360 appears to make customization very easy, even by users of average skill, but it still relies on predefined process templates. In environments where processes are dynamic, ill defined, or have many dependencies, this could be a sticking point. (This is often why companies choose to use spreadsheets to manage processes. It allows them to cheat, when necessary.) One potential challenge with PLM 360 may be scalability. The product looks great now, but scaling it, both in capability and capacity, while maintaining its usability is key. The critical element with tools of this sort is architecture. If Autodesk got the core software architecture of PLM 360 right, it’ll be able to scale. (Think Google, or Facebook.) PLM 360 is, according to sources inside Autodesk, built with industry standard open source components, using a workflow engine that was developed by a small company acquired by Autodesk.

Autodesk PLM 360 is likely to be most interesting to companies that use Autodesk’s major applications, including AutoCAD, Revit, Inventor, 3DS Max, and Maya. But it’s also an interesting choice for anyone who is searching for a way to quickly implement some business processes in their company, without having to spend a fortune to do it.

Kenesto, the anti-PLM system

Kenesto is a cloud-based software-as-a-service business process automation system designed specifically for industry and commerce.

It’s not strictly a PLM system; it might be considered more of an anti-PLM system, in that it doesn’t assume that the processes used to manage product lifecycles are necessarily static.

Kenesto is designed to capture, document, and automate loosely coupled long-running product-centric processes. Rather than requiring users to completely define processes up front, Kenesto captures processes as they’re being executed. Users just do the things they’d typically do, such as sending emails and attachments, and Kenesto keeps track of them, and records and documents the processes as they unfold.

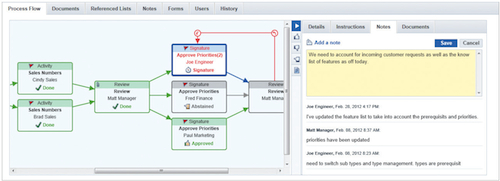

Kenesto represents processes as simple block diagrams, showing status and notes

In other PLM or business process automation systems, you need to rely upon predefined process models that may not be up-to-date, and may not match the way the team currently works. (And may or may not require experts or consultants to modify.) Kenesto was built to handle the mutable and complex processes inherent to designing, developing, pricing, manufacturing and supporting products. Kenesto processes are flexible, and can be changed, extended, or added onto as they execute. It’s possible to re-work competed steps, with a “go back” capability. Process owners can control status, and skip activities that are overdue or obsolete.

Kenesto is cloud-based, and does not require the installation of any client software. It runs on any HTML5-based browser, and works on desktops, Android, and iOS devices.

While its technical design makes Kenesto easy and fast to deploy, the “magic fairy dust” that makes it really interesting is its people-centric design. Rather than imposing artificial restrictions, it recognizes the way that people and teams work in the real world: with a lot of variability. While Kenesto looks a lot like a PLM system, it doesn’t behave like one. Kenesto is currently available through a wide beta program.

Autodesk PLM 360

www.autodeskplm360.com

Kenesto

www.kenesto.com

Filed Under: ENGINEERING SOFTWARE

Evan, interesting comparison. As I can see your point on diff between Kenesto and PLM 360 mostly about process characteristic. Can you elaborate what do you mean by this –> “It’s not strictly a PLM system; it might be considered more of an anti-PLM system, in that it doesn’t assume that the processes used to manage product lifecycles are necessarily static”? Thanks, Oleg

Kenesto is not a PLM

system. Kenesto is a standalone product today that automates process steps; the

results an increase in productivity.

Kenesto complements PLM systems,

CAD and others for that matter. Anti-PLM is a term that was used by the

writer, we are not PLM. That does not mean we are Anti- in a negative fashion

as the co-founders of our product are responsible for the development of those

very PLM tools. We are not a static process flow system. What we are is a

flexible product that is cloud-based automation steps enabling people to create

a business process that includes and collaborates many people, organizations

and the results of CAD product files designed in (almost anything- word doc,

pdf, 2D/3D). This allows for the inclusion of these “document” files to be added

to a process step that can be sent anywhere to anyone and viewed in the cloud

100%. (On Any device too!)

We enable people to build a

process flow in a: Rigid manner (which can be static/serial), Guided manner, or

a flexible on the fly/ad hoc manner.

Thanks for the post. I have noticed one thing – the only vendors that are mentioned are Autodesk, PTC etc what about other vendors (that a less well-know) – do they have a new approach to PLM ?

When I wrote the article, I didn’t know about DEXMA (http://dexma-plm.com).

If you have time please have a look. Or you can email us to ask for a demo. Thanks !