Portescap introduces Athlonix™ high-power density brush DC motors. These compact, high-efficiency endurance motors deliver unrivaled speed-to-torque performance in a compact lighter weight package (15-53 grams depending on frame size) with output power up to 9 watts. Athlonix motors feature an energy efficient coreless design with an optimized self supporting coil and magnetic circuit, which delivers maximized power density and sustained endurance over the life of the motor. They are available in 12, 16 and 22 mm frame sizes.

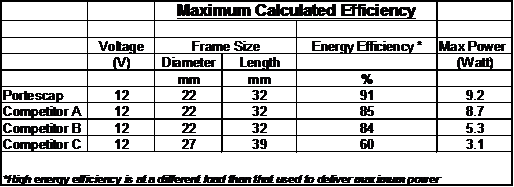

The optimized coil design leads to a low motor regulation factor with energy efficiency approaching 90%, depending on the motor load conditions. With such high efficiency, users benefit from increased performance over the life of the motor, in a more compact and lighter weight package. Additionally, less power-draw helps facilitate reduced cost-of-ownership with increased value-in-use for the end-user.

“The motor regulation factor, measured by R/k2 where R is the coil resistance and k is the torque constant, is a critical measure of motor’s power density over its performance lifetime. The lower the motor regulation factor the lower will be the heat loss at higher loads, thus enabling the motor to retain high power density with sustained endurance. The heat loss from a motor is detrimental not only in terms of reduced efficiency, but it also degrades motor performance over the life of the motor. Superior motor regulation, then, is the key to levels of performance and endurance that set Athlonix apart from conventional technologies,” says Dr. Senapati.

A typical 22 mm coreless motor that is operating at high load of 15mNm for 5000 hours can see performance degrade due to the thermal heat it has generated, while at the same time having less power and less energy efficiency due to higher motor regulation factor. Athlonix motors have motor regulation factors that are lower by 5-20% than most comparative motors available today, resulting in consistent power density over the life time of the motors.

With maximum continuous torque up to 16.5 mNm and superior angular acceleration, Athlonix motors deliver higher throughput than comparative motors by quickly and efficiently accelerating to the desired speed. As a result, they are ideally suited for use in automation applications such as medical analyzers and electronic assembly that require constant pick-and-place operations during machining, assembly and scanning. Their endurance and high performance, energy efficient operation also makes them well suited for use in medical pumps, secure door locks, watch winding mechanisms and robotics, among others.

Athlonix motors are compatible with incremental encoders and gearheads of various sizes and ratios. They are manufactured in an ISO certified facility, and are RoHS compliant.

Filed Under: Green engineering • renewable energy • sustainability, Motion control • motor controls, Motors • dc

Tell Us What You Think!