What design problems would you solve if you could precisely control magnetic forces so that you could design specific alignment, coupling, and release forces? Engineers at Correlated Magnetics Research (CMR), LLC have developed magnetic structures that can be “programmed” using the principles of signal correlation and coding theory. They can produce unique magnetic identities to control how magnetic structures interact. These magnetic structures, referred to as correlated magnetic structures or Coded Magnets™, can be much stronger than conventional magnets yet much safer since they have less far field strength.

Conventional magnets have a few limitations:

–Their magnetic interaction is binary; they either attract or repel each other depending on their relative polarity orientation.

–Their holding force typically requires an equally strong release force.

–Translational surface alignment of two coupled magnets is unpredictable. Magnets may only partially align if the force between their surfaces is at least equal to the torque tending to orient their magnetic moments. Generally, two magnets associated with two objects cannot be depended upon to provide precision translational surface alignment since the magnets can couple and remain misaligned when the two objects are brought together.

–Rotational surface alignment of two coupled magnets is unpredictable. Magnets can couple with any of multiple rotational surface alignments relative to each other (depending on their shape) as long as surfaces having opposite polarities are brought together. Round magnets will couple at any relative rotation to each other. Very strong square magnets can be coupled at any of four different rotations. Weak magnets can be coupled at any relative rotation regardless of their shape. Generally, two magnets cannot be depended upon to achieve precision rotational surface alignment.

–Strong magnetic forces can propel one magnet into another, propel nearby metal objects to the magnet or vice versa, and strong magnetic fields can have adverse effects on pacemakers, credit cards, cell phones, and other devices.

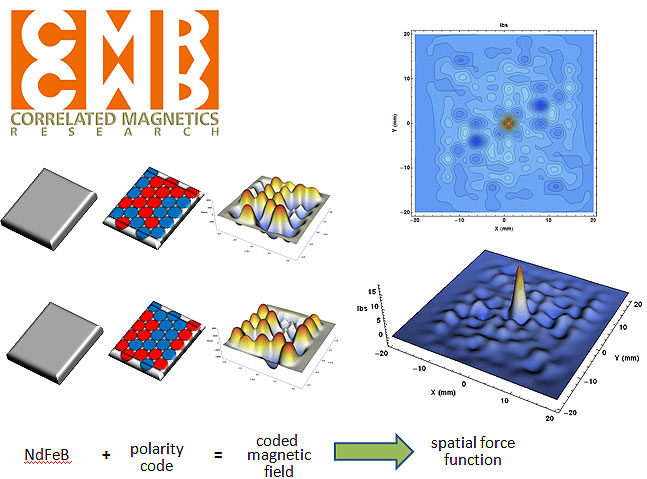

Correlated magnetics technology delivers the flexibility needed to overcome the limitations of conventional magnets. You can program, or code, the behavior of complementary magnetic structures by varying the polarity (and optionally the field strengths) of each source of the arrays of magnetic sources making up each structure. This capability, along with a cost-effective manufacturing capability, provides a multi-dimensional framework for design and development of magnets having unique spatial force functions that meet specific alignment, coupling, and release criteria. Magnetic structures can be one-dimensional, two-dimensional, three-dimensional, and even four-dimensional if produced using an electromagnet array. A magnetic structure can be composed of a coded array of discrete magnetic sources (i.e., conventional magnets) or may be produced by magnetizing an array of magnetic sources on a magnetizable material in accordance with a code.

CMR takes commercially produced rare-earth or other magnetic materials and imparts a pattern of magnetized regions with varying polarity shown here in red and blue, which yields a composite magnetic field that exhibits a dramatically different shape than conventional magnets. The field ultimately produces a ‘spatial force function,’ which means the magnets do what you tell them to.

Because correlation of magnetic sources in the spatial domain is much like the correlation of signals in the time domain, you can use communications coding theory to combine the polarity and strength of magnetic sources into groups with well-known behavior characteristics like those of corresponding groups of signals. Communication theory groups a series of elemental signals into complex sequences in the time domain. On the other hand, magnetic coding groups magnetic sources into arrays in the spatial domain, where a spatial force function corresponds to a correlation function.

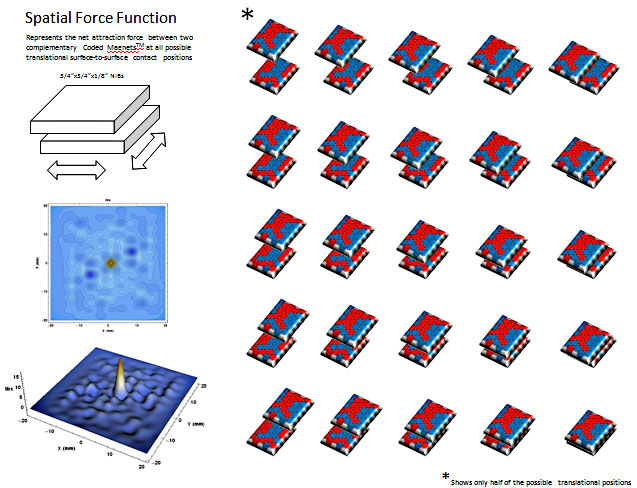

A spatial force function is a useful construct to describe the behavior among two or more correlated magnetic structures. The measurement of the total force between two correlated magnetic devices, and a three dimensional plot showing the net attraction force between these devices at all possible spatial orientations shows graphically what you can expect in terms of device behavior. These particular spatial force function plots represent coded magnets at surface contact and in all possible translational spatial orientations, thus neglecting any kind of rotation, which is obviously an additional consideration in the real world. The two-dimensional and three-dimensional plots show the peak attractive force magnitude and location, and depict the ‘side lobes’ in magnitude, direction, and location. The 25 relative position graphics represent only half of the possible translational positions at surface contact.

CMR engineers have determined at a broad level that correlated magnetic structures can have the following characteristics:

–Magnetic structures can be uniquely coded so that they will only fully correlate (and thus fully align and achieve a peak spatial force) to magnetic structures that are complementary coded.

–The coupling force can be substantially greater than a required removal force.

–The accuracy of translational surface alignment between surfaces can be precisely determined; so can the accuracy of rotational surface alignment between surfaces.

–The coding of the magnetic structures produces a ‘shortest path effect’ that results in their having an increased near field density and a decreased far field density when compared to conventional magnets.

Depending on the density and size of the coded surface, hundreds or even thousands of unique two-dimensional codes are possible. Borrowing from communication coding theory, where coding is used to provide separate communication channels, these codes can be devised to maximize “orthogonality,” or complete coupling forces between families of coded magnets. Selection of pairs of codes in one family will enable coupling and alignment within that family, but very little coupling between two coded magnet structures from different families.

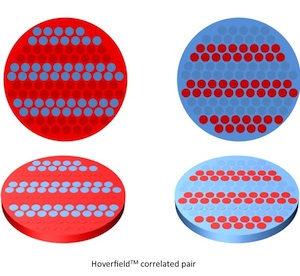

The CMR engineers have developed two distinct prototype multi-level magnetic devices, each featuring a pair of Coded MagnetsTM programmed to both attract and repel simultaneously. One prototype is the HoverfieldTM magnets, which are bound to each other through the proximity of their strong magnetic fields, yet the magnet surfaces do not touch. The magnets are held apart by a repel force encoded into the magnet surface, shorter in its reach yet stronger than the “long throw” attract force. The resulting bond is an engineered permanent balance between two opposing magnetic forces, and does not rely on mechanical hardware for attachment.

In the HoverfieldTM coded pair, the red background and red maxels represent a ‘north’ direction of polarity, and the blue background and blue maxels represent a ‘south’ direction of polarity. (Maxels are pixel-like magnetic sources.) In simplified terms, the general idea behind “multi-level magnetism” is this: the physics are such that, because the blue (south) maxels are printed on a red (north) disk, and the red (north) maxels are printed on a blue (south) disk, the coded pair will function with a ‘long-throw’ attract force (proportional to the size of the radius of the magnet disks) and simultaneously a ‘short-throw’ repel force (proportional to the size of the radius of the maxels).

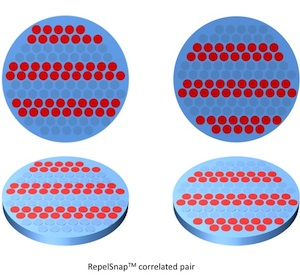

The second prototype consists of two RepelSnapTM magnets attached at their surface by a strong “short throw” attract force. When the magnet pair are moved out of their correlated attach position, the attraction forces are cancelled and the magnets instantly yield to a longer-range repel force, pushing the magnets apart.

The RepelSnapTM coded pair is essentially the opposite implementation of the same concept; a long-throw repel and short-throw attract. As these two CM devices approach each other, they want to repel each other. If you defeat the repel force (with your finger), the strong attract force is encountered and they ‘snap’ together.

Magnetic fields and forces are programmed by encoding a spatial pattern of “north” and “south” polarities onto two or more surfaces. The surfaces respond to each other according to the way the aggregate magnetic fields are programmed to correlate to each other.

The HoverfieldTM magnets allow objects to engage and attach without contact, suitable for applications from doors that close quietly to high-efficiency reduced-wear automation. RepelSnapTM correlated magnets repel in the far field but attract in the near field. They are suitable as a replacement of mechanical springs and can supply programmable, repeatable, permanent hysteresis.

In addition to multi-level magnetic behavior, correlated magnetic structures have been developed for precise alignment to prescribed tolerances and with unique identities to enable discrimination among devices.

There are a number of ways to create a Coded Magnet, but the advent of a Magnetizer (described below) enables exploration of code design in several dimensions, materials variation, behavior, and performance.

–Build ’em. You can create correlated magnetic field structures by binding together arrays of permanent magnets such that the surfaces exhibit a combination of north-facing and south-facing poles according to the desired or prescribed geometric pattern, or code.

–Stencil ‘em. An alternative method would be to create a correlated magnetic field structure (as described above) to use as a ‘template’ to impart the coded pattern onto a single, monolithic piece of ferromagnetic material, much like a stencil. To accomplish this, the ferromagnetic material would be heated to its Curie temperature (the temperature at which it becomes ‘demagnetized’), mated to the CM template, and allowed to cool in the presence of the template’s magnetic field. Once cooled, the template can be removed, and the ferromagnetic material will retain the coded pattern of polarities.

–Print ‘em. Correlated Magnetics Research has developed a magnetizing circuit that sends a high-voltage current into an inductor that will magnetize an isolated location on a piece of magnetizable material, much like a dot-matrix printer. The Magnetizer will dutifully ‘print’ the correlated magnet structures as commanded by computer numerical control (CNC) software, also developed by CMR. The magnetizer can vary the polarity, size, shape, and magnetic field strength (amplitude) of each magnetic element, or maxel. In this manner, new CM codes can be rapidly prototyped and tested for a large variety of engineering design purposes.

CMR will license the programmable magnets technology to manufacturers in automotive, aerospace, defense, environmental, construction, biomedical and consumer products industries.

Correlated Magnetics Research LLC

www.correlatedmagnetics.com

::Design World::

Filed Under: Factory automation, AUTOMATION, MECHANICAL POWER TRANSMISSION

Tell Us What You Think!