Users often make the choice of drive technology—pneumatic or electric—on the basis of experience alone. However, in order to identify the most energy-efficient customer solution in the field of automation, a technology-neutral comparison is required.

With the engineering software PositioningDrives, users require just a few key data in order to arrive at the right solution. Which electro-mechanical linear actuator best meets requirements? All that is needed is the input of position values, the payload and the installation position, and the software will suggest an optimized solution.

A common dimensioning process for mechanical drive and transmission components and motors prevents a duplication of safety factors, which would result in over-dimensioned electric drive systems and a waste of energy. Calculations have shown that with consistent use of Positioning Drives for dimensioning, energy costs can be reduced by up to 70%.

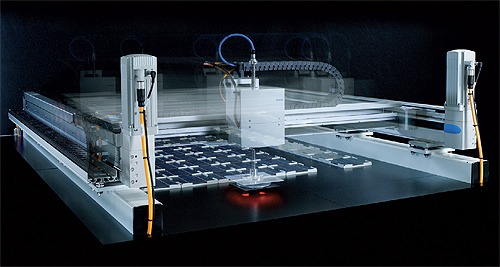

Energy-optimized solutions in the fields of handling systems and control technology can be electrically or pneumatically driven, depending on the specific application.

A similar Festo dimensioning software program helps users select the right-sized pneumatic drive. Excessively large cylinders consume air unnecessarily, while cylinders that are too small need to be operated at the maximum permissible pressure. High system pressures waste money. Air consumption can also be reduced through the use of single-acting cylinders wherever possible.

When Festo dimensioning software is used for pneumatic dimensioning, simulations take the place of costly real-life testing of the entire pneumatic control chain. If a parameter is changed, the program automatically adapts all the other parameters.

When users configure a pneumatic control chain, the program ensures that all the system components are the optimum size. This makes it possible to reduce pressure losses, pressure levels and tubing size. In the planning of the pneumatic system, short electric cables and compressed air lines help save energy.

A further factor in choosing a drive technology is that electrical systems can be overloaded for a short time only, while pneumatic systems can be overloaded over a longer period. It is therefore usually possible to use smaller sized components.

Festo Corp.

www.festo.com/us

::Design World::

Filed Under: Factory automation, AUTOMATION, Pneumatic equipment + components, FLUID POWER, Material handling • converting

Tell Us What You Think!